SK Hynix pins high hopes on specialty DRAM for AI use: CEO

Once the Yongin chip cluster is up and running in 2027, SK expects great production efficiency improvement, he says

By Oct 10, 2023 (Gmt+09:00)

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

In the semiconductor industry, it’s been quite a while since memory chips became a commodity, meaning so low an entry barrier that any chipmaker can easily mass-produce them, leading to fierce price competition.

Even for market leaders such as Samsung Electronics Co. and SK Hynix Inc., staying ahead of rivals is a matter of survival.

“Only those who break away from old commodity production methods and make new products that meet rigorous customer needs will survive,” said SK Hynix Co-Chief Executive Kwak Noh-jung in a discussion with employees to mark the company’s 40th anniversary on Tuesday.

“We must identify what our customers want. Only when we meet their specifications, will the door of our future open for us.”

He said SK Hynix, the world’s second-largest memory chipmaker, will be able to overtake market leader Samsung if it becomes the leader in specialty DRAM products, particularly in the era of artificial intelligence (AI).

AI CHIP LEADER

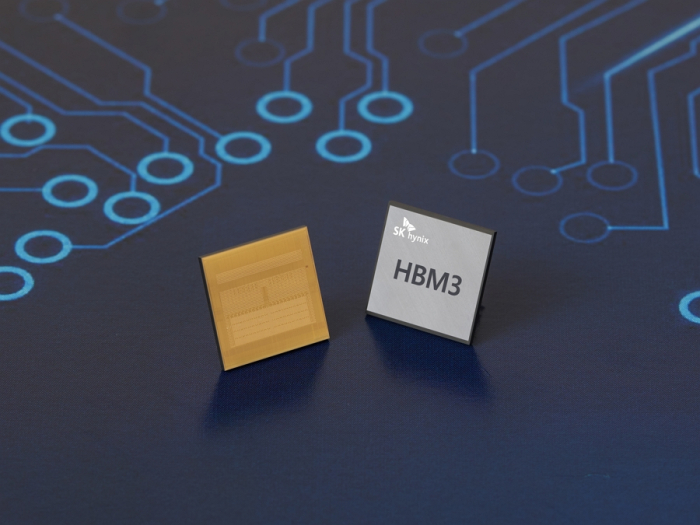

He said the company is already leading the industry in some AI chips with its cutting-edge technologies, including the world’s first mass-produced HBM3 chip and the industry’s best-performing HBM3E chip.

In April, SK said it developed the world’s first 12-layer DRAM product with a 24 gigabyte (GB) memory capacity, the industry’s largest.

Called HBM3, short for High Bandwidth Memory 3, the chip is the fourth-generation DRAM memory, succeeding the previous generations – HBM, HBM2 and HBM2E – and is the slimmest of its kind.

In August, the company unveiled HBM3E, the industry’s best-performing DRAM chip for artificial intelligence applications, and provided samples to its client Nvidia Corp. for performance evaluation.

HBM3E, the extended version of HBM3, is fifth-generation DRAM memory.

Following the mass production of HBM3E expected in the first half of next year, chipmakers will be asked to closely work with their customers from the chip design stage to meet specific requirements, CEO Kwak said.

“As the pace of AI tech advancement accelerates with the emergence of generative AI services such as ChatGPT, the type of AI services will differ from company to company. This will result in distinct memory specifications for every individual company around the world,” he said.

HYBRID DRAM

The CEO predicted that the semiconductor industry will soon witness the technological convergence of memory, central processing units (CPUs) and system chips, broadening the application of memory chips.

“As products such as PIM, which puts computational functions in memory itself, become more sophisticated, memory chips will be used even in quantum computing technology,” he said.

PIM, short for processing-in-memory, is a next-generation technology that adds computational capabilities to memory chips to help ease data movement congestion in AI and big data processing.

Asked about the planned expansion of its domestic production facilities, the chief executive said SK’s chip cluster in Yongin, Gyeonggi Province, will begin operations in 2027.

“Once the cluster is up and running, it will join our existing plants in Icheon and Cheongju to form three key pillars, making it possible to create an optimized production system and enhance our business efficiency,” he said.

He thanked employees for their hard work, which resulted in the development of industry-leading products, including DDR5 and LPDDR5 chips and the 321-layer NAND chip.

Write to Jeong-Soo Hwang at hjs@hankyung.com

In-Soo Nam edited this article.

-

Artificial intelligenceSK Hynix tests new AI hardware on Meta’s generative AI model

Artificial intelligenceSK Hynix tests new AI hardware on Meta’s generative AI modelSep 18, 2023 (Gmt+09:00)

2 Min read -

Korean chipmakersSK Hynix leads DRAM industry’s Q2 revenue rebound, retakes No. 2 spot

Korean chipmakersSK Hynix leads DRAM industry’s Q2 revenue rebound, retakes No. 2 spotAug 25, 2023 (Gmt+09:00)

2 Min read -

Korean chipmakersSK Hynix provides samples of best-performing HBM3E chip to Nvidia

Korean chipmakersSK Hynix provides samples of best-performing HBM3E chip to NvidiaAug 21, 2023 (Gmt+09:00)

3 Min read -

Korean chipmakersSK Hynix’s LPDDR5T chip likely mounted on MediaTek’s Dimensity

Korean chipmakersSK Hynix’s LPDDR5T chip likely mounted on MediaTek’s DimensityAug 10, 2023 (Gmt+09:00)

3 Min read -

Korean chipmakersSK Hynix unveils another NAND to win chip stacking war

Korean chipmakersSK Hynix unveils another NAND to win chip stacking warAug 09, 2023 (Gmt+09:00)

2 Min read -

Korean chipmakersSamsung, SK Hynix in next-generation HBM chip supremacy war

Korean chipmakersSamsung, SK Hynix in next-generation HBM chip supremacy warJul 10, 2023 (Gmt+09:00)

3 Min read -

Korean chipmakersAI-driven GPU, advanced chip shortage: Boon for Samsung, SK Hynix

Korean chipmakersAI-driven GPU, advanced chip shortage: Boon for Samsung, SK HynixMay 31, 2023 (Gmt+09:00)

3 Min read