Samsung on smooth track to 1.4 nm foundry tech to take on TSMC

It also plans to begin a new foundry service for power chips in early 2025 as it beefs up its chip design IP partnerships

By Jun 28, 2023 (Gmt+09:00)

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

SILICON VALLEY – Samsung Electronics Co., the world’s largest memory chipmaker, on Tuesday unveiled details of its advanced process roadmap to take on its archrival, Taiwan Semiconductor Manufacturing Co. (TSMC), in the artificial intelligence era.

At its annual foundry forum in San Jose, California, the South Korean tech giant also said it will begin contract chipmaking services for next-generation power management chips targeting automotive applications, including electric vehicles, from 2025.

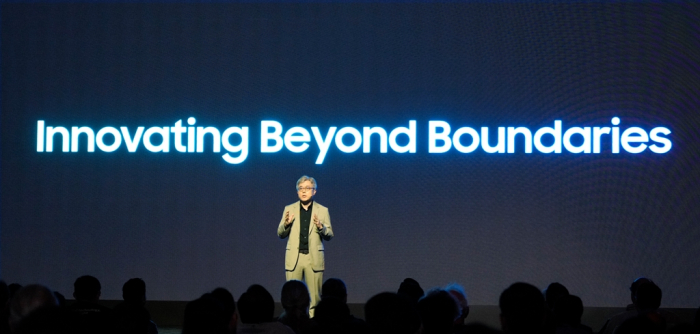

“We have always met customer needs by being ahead of the technology innovation curve, and today, we are confident that our gate-all-around (GAA)-based technology will be instrumental in supporting the needs of our customers using AI applications,” said Choi Si-young, Samsung’s foundry business chief, at the Samsung Foundry Forum 2023.

“Ensuring the success of our customers is the most central value to our foundry services.”

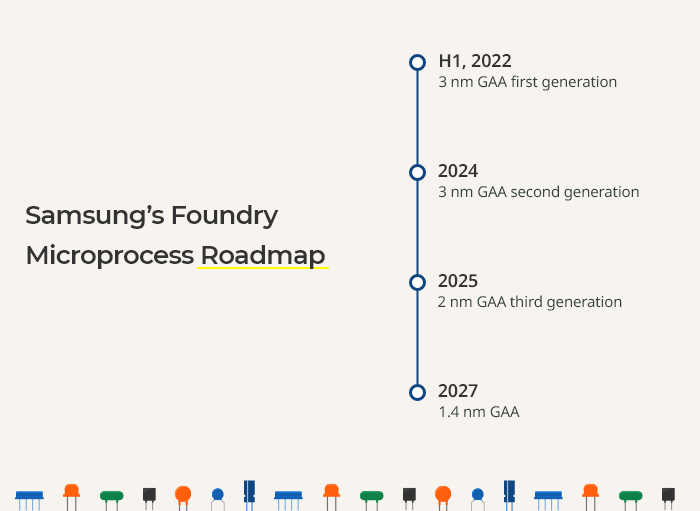

As announced earlier, Samsung said it will begin mass production of the 2-nanometer process for mobile applications in 2025 before expanding to other uses in later years.

It said it will apply the advanced 2 nm technology to high-performance computing (HPC) chips for supercomputers and computer clusters in 2026 and then to automotive chips in 2027.

MOVE TO 1.4-NANOMETER TECH BY 2027

Looking ahead, Samsung also confirmed its plans to begin mass production of more advanced 1.4 nm chips by 2027.

Chipmaking processes carry a numerical label that loosely denotes the size of the transistors that can be packed on a chip. The number refers to the thickness of the circuitry that can be drawn on the transistor. The lower the number, the more advanced the technology.

With demand for high-performance chips rising, competition for technology advancement is also fierce, particularly between foundry leader TSMC and fast-follower Samsung.

While Samsung’s production tech is based on GAA transistor architecture for its microfabrication process, TSMC uses a different technology in the fin field-effect transistor (FinFET) structure.

Samsung said its most advanced 2 nm chips have shown a 12% performance increase and 25% improvement in power efficiency over its previous 3 nm process, which it launched last year.

POWER MANAGEMENT CHIPS

At Tuesday’s event, Samsung said it will start offering contract manufacturing services for 8-inch gallium nitride (GaN) power semiconductors, which support a range of consumer, data and automotive applications. The services will become available in 2025.

In the first half of that year, the company will start producing 5 nm radio frequency (RF) chips to support 6G networking technology. The RF chips will provide a 40% increase in power efficiency over its previous 14 nm-based RF chips.

Samsung said it has formed a new Multi-Die Integration Alliance with its partner companies to create new, customized packaging technologies for applications in HPC and automotive industries.

As ultra-fine chipmaking processes are posing technological challenges, Samsung said it plans to use AI and big data technology in its chipmaking process to enhance productivity and refine product quality.

This year’s event drew over 700 guests from its foundry partners, and 38 companies set up booths to showcase the latest technology trends.

TO EXPAND CAPACITY UNDER SHELL-FIRST STRATEGY

Under the “Shell-First” operation strategy that aims to better respond to customer needs, Samsung said it will increase its manufacturing capacity.

It plans mass production of foundry products for mobile and other applications at Pyeongtaek Line 3 in the second half of this year.

The company operates contract chipmaking facilities in Giheung, Hwaseong and Pyeongtaek in Korea; as well as in Austin, Texas, with the construction of a new $17 billion fab in Taylor set for completion by the end of this year beginning operation in the second half of 2024.

By 2027, Samsung will have expanded its total cleanroom space by 7.3 times from its area in 2021, it said.

STRENGTHENED PARTNERSHIPS

Samsung, which is also hosting Samsung Advanced Foundry Ecosystem (SAFE) Forum 2023 in San Jose until Wednesday, is seeking to expand its chip design intellectual property (IP) partnerships with its clients to create a stronger contract chipmaking ecosystem.

With its 23 electronic design automation (EDA) partners, Samsung offers over 80 chip design tools. It is also collaborating with 10 outsourced semiconductor assembly and test (OSAT) partners to develop 2.5D and 3D packaging design solutions.

Separately, it is working with nine design solution partners (DSPs) and nine cloud partners.

Samsung said it has so far secured a portfolio of over 4,500 key IPs from 50 global IP partners.

The company plans to host another round of the foundry forum in Korea on July 4, and in Europe and Asia later this year.

Write to Jin-Suk Choi and Jeong-Soo Hwang at iskra@hankyung.com

In-Soo Nam edited this article.

-

Korean chipmakersSamsung unveils 1.4 nm tech roadmap to challenge TSMC’s dominance

Korean chipmakersSamsung unveils 1.4 nm tech roadmap to challenge TSMC’s dominanceOct 04, 2022 (Gmt+09:00)

4 Min read -

Korean chipmakersIntel’s foundry revamp sets off alarm bells for Samsung, TSMC

Korean chipmakersIntel’s foundry revamp sets off alarm bells for Samsung, TSMCJun 22, 2023 (Gmt+09:00)

4 Min read -

Korean chipmakersSamsung to apply AI, big data tech to entire chipmaking process

Korean chipmakersSamsung to apply AI, big data tech to entire chipmaking processJun 19, 2023 (Gmt+09:00)

3 Min read -

Korean chipmakersSamsung takes on TSMC with strengthened chip design IPs

Korean chipmakersSamsung takes on TSMC with strengthened chip design IPsJun 14, 2023 (Gmt+09:00)

4 Min read -

Korean chipmakersShell-First: Samsung Foundry’s custom-tailored new operation strategy

Korean chipmakersShell-First: Samsung Foundry’s custom-tailored new operation strategyNov 30, 2022 (Gmt+09:00)

4 Min read -

Korean chipmakersSamsung sets sights on GAA tech to overtake TSMC in foundry

Korean chipmakersSamsung sets sights on GAA tech to overtake TSMC in foundryNov 29, 2022 (Gmt+09:00)

6 Min read -

Korean chipmakersSamsung to make 3 nm chips for Nvidia, Qualcomm, IBM, Baidu

Korean chipmakersSamsung to make 3 nm chips for Nvidia, Qualcomm, IBM, BaiduNov 22, 2022 (Gmt+09:00)

3 Min read -

Korean chipmakersSamsung’s $17 billion new chip plant in Taylor aims to rein in TSMC

Korean chipmakersSamsung’s $17 billion new chip plant in Taylor aims to rein in TSMCNov 24, 2021 (Gmt+09:00)

4 Min read -

Korean chipmakersSamsung to make 2-nanometer GAA chips by 2025 to overtake TSMC

Korean chipmakersSamsung to make 2-nanometer GAA chips by 2025 to overtake TSMCOct 07, 2021 (Gmt+09:00)

3 Min read