Samsung Electro-Mechanics unveils chip substrate for autonomous driving

As autonomous driving requires a growing number of high-performance chips, Samsung plans to expand its FC-BGA lines

By Feb 27, 2023 (Gmt+09:00)

Hankook Tire buys $1 bn Hanon Systems stake from Hahn & Co.

NPS to hike risky asset purchases under simplified allocation system

UAE to invest up to $1 bn in S.Korean ventures

Osstem to buy BrazilŌĆÖs No. 3 dental implant maker Implacil

US multifamily market challenges create investment opportunities

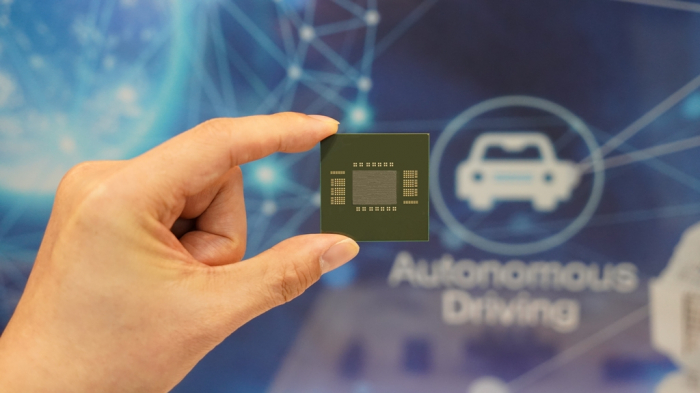

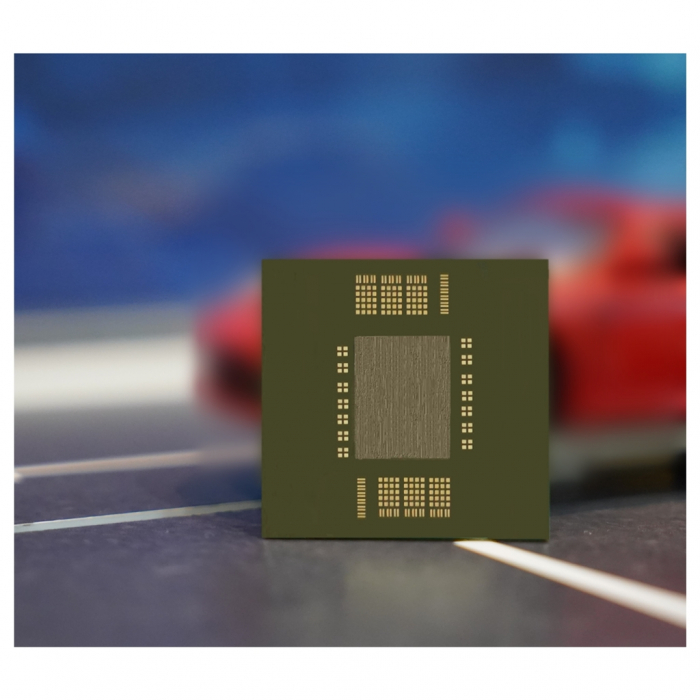

Samsung Electro-Mechanics Co. has developed an advanced semiconductor substrate for autonomous driving, which is expected to drive the top South Korean electronic component makerŌĆÖs sales and profit growth.

In line with the advancement of self-driving technology, autonomous driving systems require a growing number of high-performance and high-reliability chips that can process large amounts of data at high speed without latency even in extreme driving conditions, it said.

ŌĆ£As the demand for high-end, high-performance semiconductors continues, FC-BGA is becoming the key to differentiating semiconductor performance,ŌĆØ said Kim Eung-soo, executive vice president of the package solution unit at Samsung Electro-Mechanics.

FC-BGA is a package substrate that transmits electrical signals and power by connecting high-density semiconductor chips to the mainboard. It is mainly used for central processing units (CPUs) and graphics processing units (GPUs) that require high-performance and high-density circuit connections.

AI, SELF-DRIVING CARS DRIVE FC-BGA DEMAND

As chipmakers are shifting toward high-density circuit substrates containing more microcircuits to improve system performance, multi-layer substrates like the FC-BGA type are replacing general substrates for electronic components of artificial intelligence, autonomous driving cars and computer servers.

Samsung Electro-Mechanics said its new microcircuit technology has reduced the circuit width and spacing by 20% compared to its existing substrates and enabled more than 10,000 bumps ŌĆō input and output terminals that connect chips and substrates ŌĆō in a space that's the size of a passport photo.

The company said the new product also obtained AEC-Q100 certification, a reliability test standard for automotive electronic parts, expanding the application of the latest FC-BGA substrate to other uses such as the vehicle body, chassis and infotainment systems.

Samsung said it will expand its lineup of high-end automotive semiconductor substrates to become the market leader in the segment.

Since starting the package substrate business in 1991, Samsung Electro-Mechanics has been supplying products to major companies, including Apple Inc., Qualcomm Inc. and Intel Corp.

Samsung is already the No. 1 player in the chip package substrates for mobile application processors (APs).

The company has been investing heavily to expand its FC-BGA facilities in Korea and abroad.

Samsung has so far focused on the manufacture of its flagship product,┬Āmulti-layer ceramic capacitors┬Ā(MLCCs).

MLCCs control the flow of electricity to provide power to semiconductors. They are essential components of a variety of electronic products, including cars, smartphones, home appliances and laptops.

Write to Jeong-Soo Hwang at hjs@hankyung.com

In-Soo Nam edited this article.

-

Korean chipmakersSamsung to supply chip substrate for AppleŌĆÖs next-gen M2 processor

Korean chipmakersSamsung to supply chip substrate for AppleŌĆÖs next-gen M2 processorApr 21, 2022 (Gmt+09:00)

3 Min read -

Korean chipmakersSamsung Electro-Mechanics to invest $245 mn more in capex

Korean chipmakersSamsung Electro-Mechanics to invest $245 mn more in capexMar 22, 2022 (Gmt+09:00)

2 Min read -

Corporate strategySamsung Electro-Mechanics to focus on IT, automotive electronics sectors

Corporate strategySamsung Electro-Mechanics to focus on IT, automotive electronics sectorsMar 10, 2022 (Gmt+09:00)

1 Min read -

Samsung Electro-Mechanics poised to benefit from HuaweiŌĆÖs troubles, rising demand for MLCCs

Samsung Electro-Mechanics poised to benefit from HuaweiŌĆÖs troubles, rising demand for MLCCsSep 09, 2020 (Gmt+09:00)

3 Min read