Batteries

SK On-Ford Motor EV battery joint venture breaks ground in Kentucky

In an aim to become the world’s No. 3 battery maker by 2030, SK is also planning on a US JV with Hyundai Motor

By Dec 06, 2022 (Gmt+09:00)

3

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

NEW YORK – SK On Co., a leading South Korean battery maker, and Ford Motor Co. have begun building their multi-billion-dollar joint venture in the US state of Kentucky to support the US auto giant’s rollout of its electric cars, including the Ford F-150 Lightning pickup.

The partners broke ground for the two battery plants of the 50:50 joint venture, BlueOval SK, in Glendale, Kentucky on Monday local time with an aim to start commercial production in the first quarter of 2025.

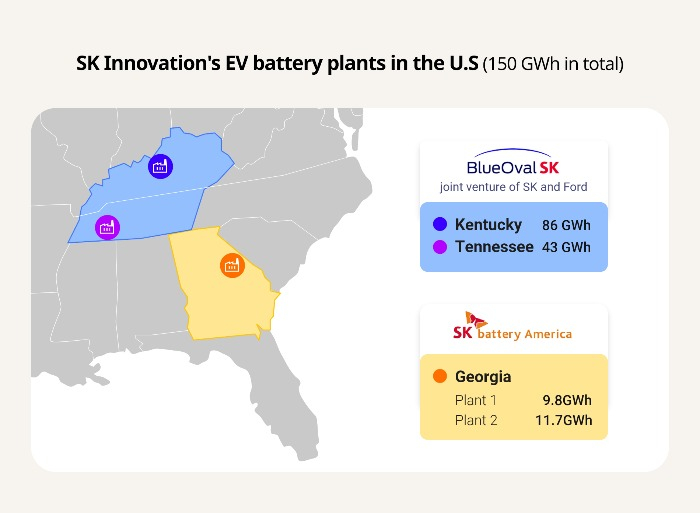

Once completed, plants 1 and 2 with a combined annual production capacity of 86 gigawatt-hours (GWh) will produce lithium-ion batteries largely for electric Ford and Lincoln vehicles, the Korean company said on Tuesday.

The $5.8 billion BueOval SK Battery Park will have the largest production capacity for a single battery campus in the US.

The JV is part of the $11.4 billion investment the two companies announced in September last year to build two EV battery manufacturing facilities in Kentucky and another in Tennessee.

The $5.6 billion Stanton, Tennessee plant, called BlueOval City, with an annual production capacity of 43 GWh will break ground by the end of this year, with production also projected to start in 2025.

For Ford, its share of the investment marks the single largest spending in its 118-year history.

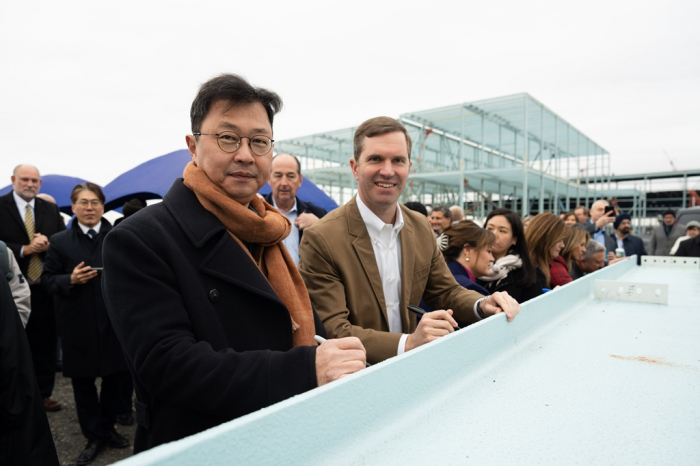

Among the attendees at the Kentucky groundbreaking ceremony were SK Group Executive Vice Chairman Chey Jae-won, SK On President Jee Dong-seob, BlueOval SK Chief Executive David Hahm, Ford Workforce Development Director Liliana Ramirez and Kentucky Governor Andy Beshear.

‘SAFEST, MOST RELIABLE BATTERIES’

“We will be manufacturing the safest and the most reliable batteries in the world,” said Chey at the event. “BlueOval SK will build the biggest and most advanced plants for EV batteries, and Kentucky will become a vital center for the future of clean mobility.”

The three factories’ combined annual capacity will reach 129 GWh, enough to power about 1.2 million units of the Ford F-150 Lightning, the electric version of America’s best-selling pickup.

Combining the production capacity of the three BlueOval plants with SK’s other two EV battery factories in Georgia, the Korean company’s entire annual capacity in the US will reach 150 GWh by 2025.

At last week’s media conference in New York, SK On’s chief Jee said the company aims to rise to become the world’s third-largest battery maker by 2025 from its current fifth position holding a 6.2% global market share.

The new battery plants come as the Korean government, carmakers and battery manufacturers are scurrying to work out measures to respond to the Inflation Reduction Act (IRA), which requires that a certain percentage of the critical minerals used in EV batteries originate from the US or its free trade partners.

“Our batteries made in the US use minerals from its trade partners such as Australia and Chile,” Jee said. He added that SK On and another Korean company, LG Energy Solution Ltd., are among those well-prepared for the IRA.

SK-HYUNDAI JOINT VENTURE IN US

In the US, SK’s batteries are supplied to Ford for its F-150 Lightning, Hyundai Motor Co. for the IONIQ 5 crossover and Kia Corp. for the EV6.

“We plan to expand our cooperation with Hyundai and other automakers for the supply of more batteries. We’re also planning on a battery joint venture with Hyundai in the US,” Jee said.

SK On aims to become the world’s No. 1 battery maker by securing a production capacity of 500 GWh by 2030, he said.

Ford, which ranks second in the US EV market after Tesla Inc., also aims to dominate the electric pickup truck market with the success of the F-150 Lightning.

“Ford’s roots run deep in Kentucky, and BlueOval SK is going to help Ford to lead the EV revolution, bringing thousands of new, high-tech jobs to the Bluegrass State,” said Lisa Drake, vice president of Ford EV Industrialization.

SK and Ford said they expect to create about 11,000 new jobs through the mega campuses in Kentucky and Tennessee.

As part of their plan to beef up recruitment, BlueOval SK in Kentucky will have a new Elizabethtown Community and Technical College BlueOval SK Training Center on its site by 2024.

Write to Hyung-Kyu Kim and Jae-Kil Cho at khk@hankyung.com

In-Soo Nam edited this article.

More to Read

-

BatteriesSK Innovation, Ford to invest $11.4 billion to build largest EV battery JV

BatteriesSK Innovation, Ford to invest $11.4 billion to build largest EV battery JVSep 28, 2021 (Gmt+09:00)

3 Min read -

BatteriesFord CEO heads to Korea to discuss EV tax credit with LG Energy, SK On

BatteriesFord CEO heads to Korea to discuss EV tax credit with LG Energy, SK OnSep 16, 2022 (Gmt+09:00)

3 Min read -

-

Comment 0

LOG IN