Batteries

LG’s $5.5 billion LFP, ESS battery plants in Arizona to kick off in 2026

With its single largest US investment, LG will boast one of the world’s first 46-series and ESS-exclusive battery plants

By Apr 04, 2024 (Gmt+09:00)

3

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

LG Energy Solution Ltd., the world’s second-largest battery maker, said on Thursday its 7.2 trillion won ($5.5 billion) battery complex in Arizona is on track to completion in two years, further enhancing its presence in the North American electric vehicle market.

The complex, announced in March 2023, consists of two manufacturing facilities – one for cylindrical batteries used in electric vehicles and the other for lithium iron phosphate (LFP) pouch-type batteries used in energy storage systems (ESS).

The complex marks the South Korean company’s single largest investment in constructing an independent battery manufacturing facility in the US.

When fully operational, the battery complex in Queen Creek – LG’s second standalone factory – will have an annual production capacity of 53 gigawatt hours (GWh) – 36 GWh for cylindrical batteries and 17 GWh for LFP ESS batteries.

The construction of the cylindrical battery plant is expected to be completed in late 2025 and that of the LFP battery plant in the following year.

Once construction work is complete, both facilities are expected to begin production in 2026.

To secure a high-quality workforce to operate the state-of-the-art manufacturing complex, LG will begin hiring at the end of this year with a plan to create several thousand new quality jobs.

LG held a stakeholders’ meeting in Queen Creek on Wednesday to provide updates on the construction of the complex.

Participants of the meeting were LG executives including Brian Oh, head of the Mobility & IT Battery Division; Hyung Kim, head of the ESS Battery Division; and Richard Ra, president of LG Energy Solution Arizona.

Attendants from the US included Arizona Gov. Katie Hobbs; Sandra Watson, Arizona Commerce Authority chief executive; and Julia Wheatley, Queen Creek's mayor.

“This transformative investment will have a lasting impact not only in Arizona but across the country and moves us one step closer toward our clean energy goal,” said Gov. Hobbs.

46-SERIES CYLINDRICAL BATTERIES, LFP TYPE

The cylindrical battery plant, LG Energy Solution Arizona, will produce 46-series batteries for electric cars.

The 4680 batteries have an energy density five times higher than the 2170 type widely used in EVs.

LG plans to begin mass production of 46-series batteries at its Ochang plant in Korea in the second half of this year – the earliest among major global battery makers.

The ESS battery manufacturing facility, LG Energy Solution Arizona ESS, will produce LFP pouch-type batteries for energy storage systems.

LG said the plant is among the world’s first ESS-exclusive battery facilities. North America is the world’s largest ESS market.

Korean battery makers have concentrated on expensive nickel-cobalt-manganese (NCM) cells. However, they are now shifting gears to produce low-end LFP cells on growing demand from Tesla Inc. and other major EV makers.

“ESS plays a vital role in green energy infrastructure as it flexibly utilizes power supply,” said Kim, the LG ESS chief

LG, TOP BATTERY SUPPLIER IN US

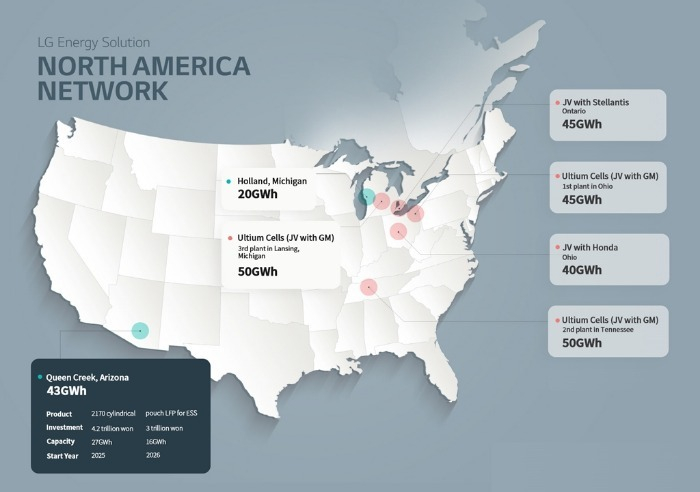

LG Energy has another independent facility in Michigan, built a decade ago, and is currently expanding to increase annual production capacity fivefold to 25 GWh by 2025 from 5 GWh.

LG Energy Solution Michigan Inc., which began operations in 2012, has been supplying batteries to major US automakers, including General Motors Co. and Ford Motor Co.

The company also has five other joint venture facilities in the US with major automakers, including GM, Japan’s Honda Motor, Korea’s Hyundai Motor Co. and multinational automaker Stellantis N.V. to provide IRA-compliant batteries.

LG Energy, a unit of Korea’s top chemicals maker LG Chem Ltd., has been increasing investment to expand its presence in the US market.

Earlier this week, LG Energy said the second plant of Ultium Cells LLC, a joint venture with its US partner GM, has begun mass production in Spring Hill, Tennessee.

LG said Ultium Cells’ second plant with a production capacity of 35 gigawatt hours (GWh) will gradually ramp up its output capacity to 50 GWh, enough to power 600,000 high-performance pure electric cars that can run 500 km on a single charge.

LG and GM’s first Ultium Cells plant with a production capacity of 35 GWh in Ohio began production in November 2022.

Write to Woo-Sub Kim at duter@hankyung.com

In-Soo Nam edited this article.

More to Read

-

BatteriesLG Energy, GM’s 2nd Ultium Cells plant begins production in Tennessee

BatteriesLG Energy, GM’s 2nd Ultium Cells plant begins production in TennesseeApr 02, 2024 (Gmt+09:00)

2 Min read -

BatteriesLG Energy to produce 4680 batteries in August for Tesla, others: CEO

BatteriesLG Energy to produce 4680 batteries in August for Tesla, others: CEOFeb 15, 2024 (Gmt+09:00)

4 Min read -

BatteriesLG Energy to supply $748 million worth of batteries to Japan’s Isuzu Motors

BatteriesLG Energy to supply $748 million worth of batteries to Japan’s Isuzu MotorsJan 26, 2024 (Gmt+09:00)

1 Min read -

BatteriesLG Energy, KAIST develop Li-Metal battery tech for improved EV range

BatteriesLG Energy, KAIST develop Li-Metal battery tech for improved EV rangeDec 07, 2023 (Gmt+09:00)

3 Min read -

BatteriesLG Energy, Ford’s battery JV in Turkey scrapped as EV uptake slows

BatteriesLG Energy, Ford’s battery JV in Turkey scrapped as EV uptake slowsNov 12, 2023 (Gmt+09:00)

3 Min read -

BatteriesLG Energy to build $5.6 billion battery complex in Arizona

BatteriesLG Energy to build $5.6 billion battery complex in ArizonaMar 24, 2023 (Gmt+09:00)

3 Min read

Comment 0

LOG IN