LG Energy may produce mid-nickel EV batteries from 2024

It also plans to bring forward the mass production of LFP batteries from 2026 to challenge CATL and BYD

By Nov 20, 2023 (Gmt+09:00)

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

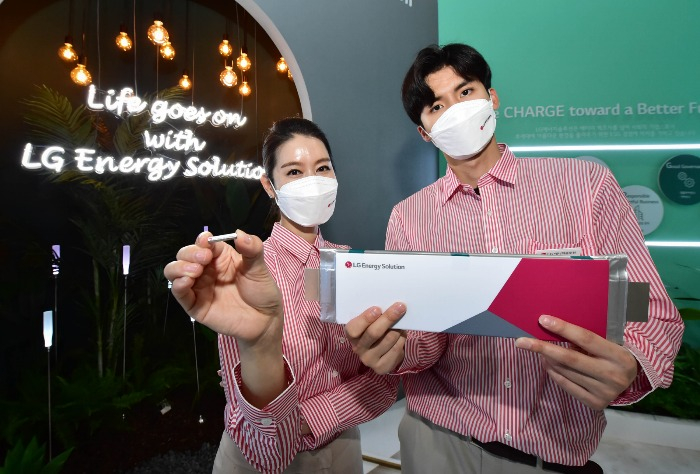

South Korea’s LG Energy Solution Ltd. plans to mass-produce mid-nickel, high-voltage lithium batteries as early as next year, one year ahead of schedule, as electric vehicle makers are increasingly adopting low-cost batteries to reduce EV prices, according to industry sources on Monday.

Mid-nickel, cobalt and manganese (NCM) batteries are cheaper than existing NCM batteries and are seen as price competitive as lithium iron phosphate (LFP) batteries.

Mid-nickel NCM batteries contain 40-60% nickel, lower than more than 80% for LG Energy’s flagship high-performance, high-nickel batteries. Their cobalt content is much lower than that of high-nickel batteries.

The high-voltage, mid-nickel NCM batteries developed by LG Energy Solution are about 10% cheaper than existing high-nickel batteries. LG has increased the mid-nickel batteries' energy density to 700-watt hours per liter, not far behind high nickel batteries.

“Automakers have continuously requested that production costs be lowered at the cost of mileage,” said an LG Energy official.

The first output of the mid-nickel NCM batteries will likely be supplied to a European automaker, which it declined to identify.

LG Energy will also bring forward the mass production of LFP batteries from 2026. Chinese companies such as CATL and BYD are leading the LFP battery market.

Kwon Young Soo, vice chairman and chief executive of LG Energy, said earlier this month that it is trying to mass-produce LFP batteries as quickly as possible, saying: “It will only take time (to build production lines), but there are no technical difficulties.”

LG Energy Solution is also developing a dry manufacturing process for batteries to become the industry's first player to introduce the technology.

The dry process does not use organic solvents when making battery electrodes. Thus, it can reduce manufacturing costs, while increasing energy density by up to twice that of the wet process.

Write to Nan-Sae Bin and Hyung-Kyu Kim at binthere@hankyung.com

Yeonhee Kim edited this article.

-

BatteriesLG Energy, Ford’s battery JV in Turkey scrapped as EV uptake slows

BatteriesLG Energy, Ford’s battery JV in Turkey scrapped as EV uptake slowsNov 12, 2023 (Gmt+09:00)

3 Min read -

BatteriesLG Energy, SK On to delay battery JVs with Ford as demand slows

BatteriesLG Energy, SK On to delay battery JVs with Ford as demand slowsNov 07, 2023 (Gmt+09:00)

4 Min read -

BatteriesLG Energy Solution to start producing cheaper EV batteries

BatteriesLG Energy Solution to start producing cheaper EV batteriesOct 25, 2023 (Gmt+09:00)

4 Min read -

EarningsLG Energy Q3 profit at record high on gains from US battery tax credit

EarningsLG Energy Q3 profit at record high on gains from US battery tax creditOct 11, 2023 (Gmt+09:00)

3 Min read -

BatteriesLG Energy barely fends off CATL in global EV battery market

BatteriesLG Energy barely fends off CATL in global EV battery marketOct 13, 2023 (Gmt+09:00)

3 Min read -

BatteriesLG Energy Solution to supply EV batteries to Toyota for 10 years

BatteriesLG Energy Solution to supply EV batteries to Toyota for 10 yearsOct 05, 2023 (Gmt+09:00)

3 Min read -

BatteriesLG Energy raises $1 bn in bonds for EV battery production

BatteriesLG Energy raises $1 bn in bonds for EV battery productionSep 19, 2023 (Gmt+09:00)

2 Min read