Batteries

Lotte to supply advanced copper foil to Doosan for Nvidia’s Blackwell

Lotte recently converted its Iksan plant, originally built for general-purpose foil, to make high-end products

By Dec 17, 2024 (Gmt+09:00)

3

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Mirae Asset to be named Korea Post’s core real estate fund operator

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

Lotte Energy Materials Corp., a leading South Korean battery materials maker, said on Tuesday it will supply advanced copper foil to Doosan Corp.'s business group (Doosan BG) for use in glass substrates.

Lotte said it will begin supplying grade-4 hyper very low profile (HVLP) copper foil for next-generation AI accelerators to Doosan later this month. Lotte is the first in the industry to mass-produce such products.

Doosan BG is a top-tier global manufacturer of copper clad laminates, an intermediate product in electric circuit boards.

Sources said Lotte Energy’s copper foil supplied to Doosan BG will end up in chip designer Nvidia Corp.’s Blackwell graphics processing unit microarchitecture.

Nvidia has secured most of its copper foil needs from another Korean firm, Solus Advanced Materials Co., and glass substrates from Taiwan’s Elite Material Co., better known as EMC.

But amid growing demand for copper foil and glass substrates, the US chip designer has expanded its parts supply chain to include Doosan and Lotte Energy, sources said.

LOTTE TO RAMP UP PRODUCTION IF NVIDIA DEMAND RISES

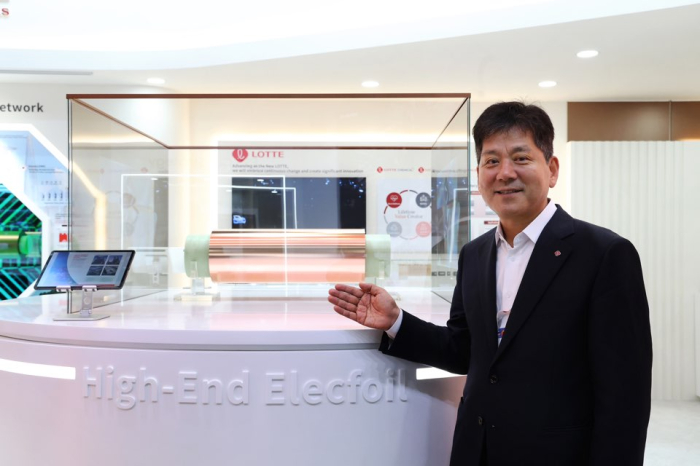

In November, Lotte Energy Materials began producing advanced grade-4 HVLP copper foil at its plant in Iksan, North Jeolla province.

The company recently converted the plant, originally built for general-purpose copper foil, to produce more advanced, high-value HVLP foil.

If Lotte runs the plant at full capacity – 1,800 tons annually – the copper foil volume to be supplied to Doosan for eventual use in Nvidia’s Blackwell products will amount to tens of billions of won (tens of millions of dollars), sources said.

If demand rises, Lotte is ready to ramp up production capacity at the Iksan plant, they said.

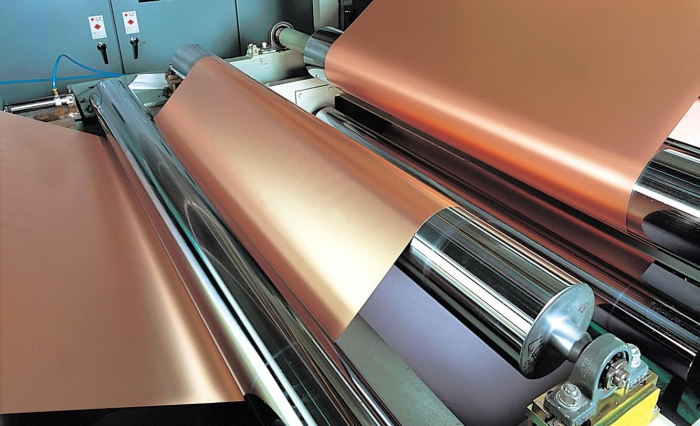

A copper foil, also known as elecfoil, is a thin foil that surrounds the anode, or negative end, of a lithium-ion battery. High-strength copper foils are essential to making safe, high-density rechargeable batteries.

Elecfoil, a thin copper foil less than 10 micrometers thick made through electrolysis of a copper sulfate solution, is also used to make cathode collectors in rechargeable lithium batteries. It is widely used in electric vehicles (EVs) and energy storage systems.

TO HIGH-END PRODUCT

Lotte Energy said it will steadily increase the proportion of high-end copper foil products, including network and semiconductor packaging copper foil.

“We are proud to supply the industry’s only recognized 4th-generation AI accelerator copper foil to our key customer, Doosan. Through this supply, we aim to solidify our value chain for AI accelerators and network applications,” said CEO Kim Yeon-seop.

Formerly known as Iljin Materials Co., Lotte Energy has been an industry player for decades, supplying its products to global EV battery makers, including China’s BYD, Korea’s LG Energy Solution Ltd. and Samsung SDI Co.

Lotte Chemical Corp., a unit of Lotte Group, bought a controlling stake in Iljin Materials for 2.7 trillion won ($1.9 billion) in 2022 and renamed it Lotte Energy Materials.

In 2022, Lotte said it developed a new ultra-high tensile elecfoil, which can significantly improve the mileage, power and stability of EVs.

Company officials expect high-end foils, which are ultra-thin, stronger and more elongated, to account for more than two-thirds of its new orders.

Write to Hyung-Kyu Kim and Woo-Sub Kim at khk@hankyung.com

In-Soo Nam edited this article.

More to Read

-

BatteriesLotte Energy to supply copper foil to Samsung SDI-Stellantis JV

BatteriesLotte Energy to supply copper foil to Samsung SDI-Stellantis JVAug 26, 2024 (Gmt+09:00)

3 Min read -

BatteriesLotte Energy Materials sets sights beyond copper foil: CEO Kim

BatteriesLotte Energy Materials sets sights beyond copper foil: CEO KimJun 21, 2024 (Gmt+09:00)

4 Min read -

BatteriesPOSCO International, Lotte Energy in $4.4 bn battery materials supply deal

BatteriesPOSCO International, Lotte Energy in $4.4 bn battery materials supply dealNov 01, 2023 (Gmt+09:00)

3 Min read -

BatteriesLotte Energy Materials aspires to become copper foil leader: CEO

BatteriesLotte Energy Materials aspires to become copper foil leader: CEOJul 04, 2023 (Gmt+09:00)

3 Min read -

BatteriesLotte Energy Materials to build copper foil plant in US for EV makers

BatteriesLotte Energy Materials to build copper foil plant in US for EV makersSep 17, 2023 (Gmt+09:00)

3 Min read

Comment 0

LOG IN