LG Electronics turns home appliance plant into smart factory

The home appliance giant plan to turn all six production lines at its main plant to a smart factory by 2024

By Sep 16, 2021 (Gmt+09:00)

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

South Korea’s LG Electronics Inc. said on Thursday it is turning its main home appliance plant into a smart factory, which improves productivity and power usage efficiency.

The home appliance giant said it has completed the first phase of its manufacturing facility upgrade at its main production base in Changwon, South Gyeongsang Province.

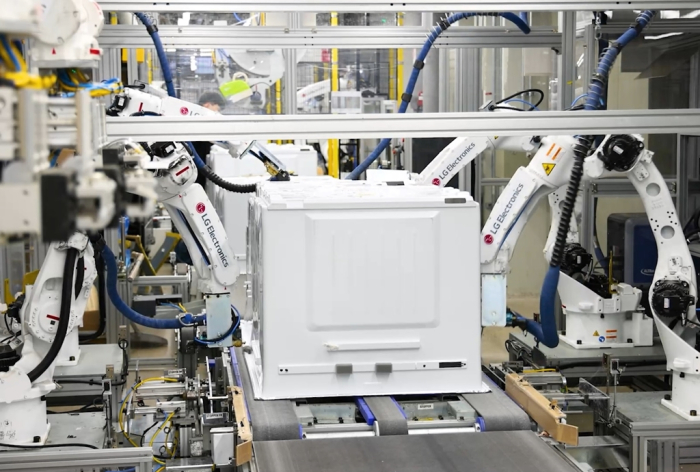

The company has turned three lines that produce refrigerator and water purifiers into an automated manufacturing system powered by artificial intelligence and robot technologies at the Changwon plant called LG Smart Park.

Of the 800 billion won ($681 million) earmarked for the factory automation, LG said it has spent 480 billion won for the first phase of the project.

The upgrade focuses on bringing production lines located at several different buildings under one roof at the LG Smart Park.

LG plans to revamp three more manufacturing lines for kitchen appliances inside the new building by 2024.

The upgraded facility will enable enhanced automation in all production processes, from assembly to packaging, and leverages big data and deep learning technology to improve work and power usage efficiency, according to LG.

To improve productivity, LG said it also beefed up its logistics system with 5G-powered automated guided vehicles (AGVs) and a smart parts delivery system.

When the entire upgrade of its Changwon 1 factory is completed, the plant's annual production capacity will increase from 2 million units to 3 million units, it said.

With the advanced system, LG expects to see 30% improvement in energy efficiency.

INDUSTRY TREND TOWARD SMART FACTORY

Analysts said an increasing number of manufacturing companies will adopt a smart factory system going forward to cut costs and improve productivity.

Hyundai Motor Co. said in July it is innovating its electric vehicle manufacturing processes.

The top Korean automaker said it is making its latest IONIQ5 EV at a highly automated smart factory, adopting AI and robot technologies.

its EV production line is designed to automatically carry out entire processes that include assembly, welding and the moving of parts, according to Hyundai.

LG Group, Korea’s fourth-largest conglomerate, said in mid-May that it will spend about 120 billion won over the next three years to establish a massive high-performance computing infrastructure for advanced artificial intelligence as part of its group-wide digital transformation.

LG Group said its research arm, LG AI Research, will develop a hyper-scale AI system that can conduct comprehensive and independent learning and decision-making by processing huge amounts of data just like the human brain.

According to global research firm MarketsAndMarkets, the size of the global smart factory market will rise at an annual average rate of 11% to $134.8 billion by 2026 from $80.1 billion this year.

Write to Hyung-Suk Song at click@hankyung.com

In-Soo Nam edited this article.

-

ElectronicsLG to expand medical equipment business with pain-relieving device

ElectronicsLG to expand medical equipment business with pain-relieving deviceNov 10, 2021 (Gmt+09:00)

2 Min read -

ElectronicsLG overtakes Whirlpool as top home appliance maker after strong Q3

ElectronicsLG overtakes Whirlpool as top home appliance maker after strong Q3Oct 29, 2021 (Gmt+09:00)

2 Min read -

ElectronicsLG Electronics brings gardening indoors with plant cultivator Tiiun

ElectronicsLG Electronics brings gardening indoors with plant cultivator TiiunOct 14, 2021 (Gmt+09:00)

1 Min read -

Chemical IndustryLG Chem, ADM to build JV in US to produce bioplastics made from corn

Chemical IndustryLG Chem, ADM to build JV in US to produce bioplastics made from cornSep 14, 2021 (Gmt+09:00)

3 Min read -

Corporate investmentLG Chem to spend $2.2 billion to build 10 new eco-friendly factories

Corporate investmentLG Chem to spend $2.2 billion to build 10 new eco-friendly factoriesAug 19, 2021 (Gmt+09:00)

2 Min read -

EnergyLG Chem to power China battery plants with 100% renewable energy

EnergyLG Chem to power China battery plants with 100% renewable energyAug 10, 2021 (Gmt+09:00)

2 Min read -

EV BatteriesHyundai Motor, LG Energy to build $1.1 bn EV battery plant in Indonesia

EV BatteriesHyundai Motor, LG Energy to build $1.1 bn EV battery plant in IndonesiaJul 29, 2021 (Gmt+09:00)

2 Min read -

ElectronicsLG Electronics sees decent growth in US home appliance business

ElectronicsLG Electronics sees decent growth in US home appliance businessJul 06, 2021 (Gmt+09:00)

2 Min read -

Revenue rankingsLG Electronics set to overtake Whirlpool as top home appliance maker

Revenue rankingsLG Electronics set to overtake Whirlpool as top home appliance makerApr 20, 2021 (Gmt+09:00)

2 Min read