Korean chipmakers

Samsung to use recycled neon gas in chip manufacturing

The Korean memory chip giant will be the industry’s first to use recovered neon gas in the photolithography process

By Mar 07, 2024 (Gmt+09:00)

2

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

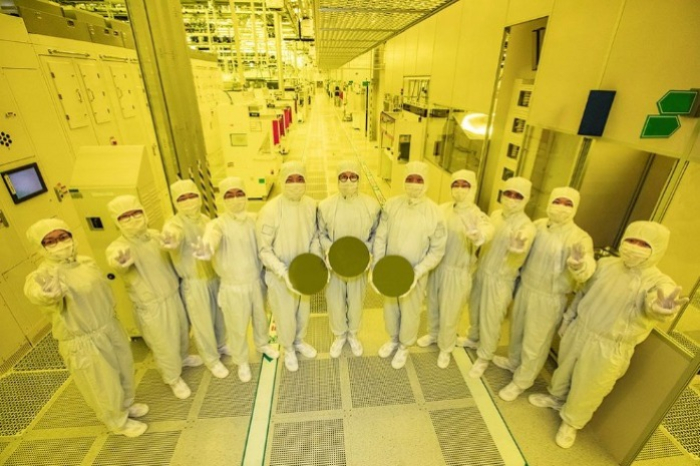

Samsung Electronics Co. will use recycled neon gas in chip production for the first time in the world, a move expected to stabilize the cost and supply of the rare noble gas, as well as lower the company’s carbon footprint.

According to sources in the semiconductor industry, the world’s largest memory chip producer has successfully used recycled neon gas in chip mass production without degrading chip quality. Encouraged by the result, the South Korean chip giant plans to use recycled neon gas in chip manufacturing from next year in what would be the world’s first of its kind.

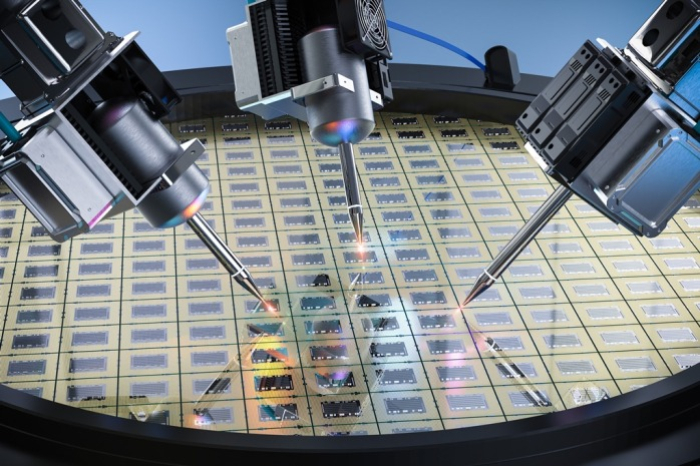

Neon gas is a rare noble gas that is also an essential raw material in the photolithography process. It is used to generate laser light to transfer a circuit pattern on a substrate, and it is also widely used in not only the semiconductor industry but also other areas such as the display sector.

Samsung Electronics has relied solely on imported neon gas, mainly sourced from Ukraine, Russia and China.

But since the outbreak of the Russia-Ukraine war in 2022, its price has skyrocketed due to a supply shortage. Its import price even soared to $1,612 per liter in 2022 from $58 in 2021.

The shockingly inflated price led Samsung Electronics to seek out supply alternatives, including the recovery of the rare noble gas from laser waste streams.

With the recycled neon gas, Samsung Electronics is expected to reduce raw material costs in chip production – both memory chip and foundry businesses.

According to data from the Korea Customs Office, Korea’s total neon gas imports in 2023 reached 102,782 liters in volume and $16.8 million in value.

TO COVER 3/4 OF NEON GAS DEMAND

The chip giant has teamed up with a local materials company to develop high-quality recycled neon gas that can be immediately used in chip manufacturing.

Samsung Electronics will capture neon gas from laser waste streams, while the local partner will purify recycled neon.

The Korean chipmaker plans to use recycled gas for 75% of its neon gas requirements for the photolithography process from next year.

This is expected to significantly reduce the company’s neon gas imports, which amount to tens of thousands of liters every year.

Considering that neon is a rare noble gas, its recycling will also guarantee its stable supply, which is good news for the country’s chip industry, which heavily relies on neon gas imports.

In response to the neon gas shortage following the Russia-Ukraine war, Samsung’s crosstown rival SK Hynix Inc., the world’s second-largest memory chip producer, in late 2022 developed neon gas production technology in partnership with TEMC Co., a Korean specialty gas producer, and POSCO, the steelmaking unit of POSCO Holdings Inc. to locally source the rare gas.

Samsung Electronics plans to continue developing technologies to recycle other essential materials for chip production to stabilize the overall chip supply chain.

The latest advancement is also expected to help Samsung Electronics reduce carbon emissions during chip production.

Recycling neon can reduce carbon emissions from the neon purification process by up to 95%, according to the chip industry.

Write to Jeong-Soo Hwang at hjs@hankyung.com

Sookyung Seo edited this article.

More to Read

-

Korean chipmakersSamsung holds DRAM supremacy with its market share at 7-year high

Korean chipmakersSamsung holds DRAM supremacy with its market share at 7-year highFeb 27, 2024 (Gmt+09:00)

2 Min read -

-

Korean chipmakersSamsung eyes $8.8 billion 2024 chip profit: sources

Korean chipmakersSamsung eyes $8.8 billion 2024 chip profit: sourcesJan 02, 2024 (Gmt+09:00)

4 Min read -

Korean chipmakersSK Hynix hikes use of locally produced neon gas for chip manufacture

Korean chipmakersSK Hynix hikes use of locally produced neon gas for chip manufactureOct 05, 2022 (Gmt+09:00)

1 Min read

Comment 0

LOG IN