[Exclusive] Battery materials

Korea’s Solus supplies battery copper foil to Tesla

Tesla to use Solus’ products to meet 70% of its demand for next-generation battery production in Texas

By Feb 16, 2022 (Gmt+09:00)

2

Min read

Most Read

Samsung steps up AR race with advanced microdisplay for smart glasses

When in S. Korea, it’s a ritual: Foreigners make stops at CU, GS25, 7-Eleven

Maybe Happy Ending: A robot love story that rewrote Broadway playbook

NPS yet to schedule external manager selection; PE firms’ fundraising woes deepen

US auto parts tariffs take effect; Korea avoids heavy hit

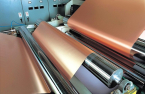

South Korea’s Solus Advanced Materials started supplying battery copper foil to Tesla Inc. in January, becoming the country’s first battery materials producer to directly sell products to the world’s top electric vehicle maker.

Tesla is using Solus’ products for the 4680 battery cell, the US EV giant’s next-generation battery, according to industry sources in South Korea.

Solus is supplying the copper foil to Tesla’s own battery plant at the new Gigafactory in Austin. The facility with a capacity of 40 gigawatt-hours (GWh) is understood to be for the production of the 4680 battery, which is 46 millimeters in diameter and 80 mm in length.

The cylindrical cell is said to have five times the energy capacity of the current lithium-ion 2170 battery and boost electric vehicles' mileage by 16%. The latest battery is expected to help Tesla cut costs as it means fewer batteries installed in the EVs.

SOLUS TO MEET 70% OF TESLA DEMAND FOR BATTERY PRODUCTION

Tesla CEO Elon Musk said the EV maker started producing the Model Ys equipped with the 4680 batteries during an earnings call for the fourth quarter of 2021. The electric sport utility vehicle will be delivered from the first quarter of 2022 after final certification, he said.

Tesla, which has been buying the 4680 batteries from Japan’s Panasonic Corp., reportedly plans to make its own cells to meet about 30% of its needs. Solus' battery copper foil supply, in turn, will satisfy about 70% of Tesla’s demand for battery production.

The US EV giant also has a battery plant at the Gigafactory in Berlin, which is expected to start mass production in the second half of this year.

Solus is predicted to supply battery copper foil to Tesla’s first manufacturing location in Europe since the South Korean company has a battery copper foil plant in Hungary.

KOREAN MAKERS TO DOMINATE GROWING COPPER FOIL MARKET

South Korea’s copper foil makers are expected to dominate the growing global market with better technologies. Customers often require thin, large and long copper foil with precise physical specifications. South Korean players are the only ones who can stably supply a massive amount of this kind of specialized product, analysts said.

Demand for battery copper foil is expected to more than triple to 1.6 million tons in 2025 from 450,000 tons in 2021, according to industry sources. South Korean producers are expanding capacity with Solus scheduled to raise output to 132,000 tons a year from 30,000 tons this year.

Carmakers are seeking direct cooperation with battery materials makers to secure stable supply and cut costs.

US top automaker General Motors Co. joined hands with South Korea’s POSCO Chemical Co. in December of last year to set up a joint venture to produce cathode materials in the US. Volkswagen AG, Europe’s largest carmaker, Belgian chemicals and recycling company Umicore agreed to create a JV for precursor and cathode materials production.

Write to Jeong Min Nam and Jung-hwan Hwang at peux@hankyung.com

Jongwoo Cheon edited this article.

More to Read

-

Battery materialsPOSCO Chemical, GM to launch new battery material JV in US

Battery materialsPOSCO Chemical, GM to launch new battery material JV in USDec 02, 2021 (Gmt+09:00)

4 Min read -

Battery materialsKorea copper foil makers on bull run amid demand hopes

Battery materialsKorea copper foil makers on bull run amid demand hopesNov 19, 2021 (Gmt+09:00)

4 Min read -

Battery materialsKorea’s SKC to build $761 mn copper foil plant in Poland

Battery materialsKorea’s SKC to build $761 mn copper foil plant in PolandNov 18, 2021 (Gmt+09:00)

1 Min read -

[Exclusive] EV batteriesCopper foil maker raises $700 mn funding to build Europe plant

[Exclusive] EV batteriesCopper foil maker raises $700 mn funding to build Europe plantApr 21, 2021 (Gmt+09:00)

2 Min read

Comment 0

LOG IN