Tech, Media & Telecom

KETI localizes core software for metal 3D printing

This breakthrough will boost self-reliance in manufacturing tech and reflect the ideas of domestic experts

By Dec 21, 2022 (Gmt+09:00)

1

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

Korea Electronics Technology Institute (KETI) on Tuesday said it developed domestic software to boost quality in manufacturing using metal 3D printers, a breakthrough expected to also break the nation's reliance on foreign products in the field.

Metal 3D printing is done by shooting a high-temperature laser at a desired location on metal powder laying flat. The powder is melted and coagulated to produce the desired item. The nation has relied on software from the US or Europe to generate laser or tool paths and output codes irradiated on metal powder. Many restrictive factors also arose in process development like the inability to gather process data due to the encryption of software output code.

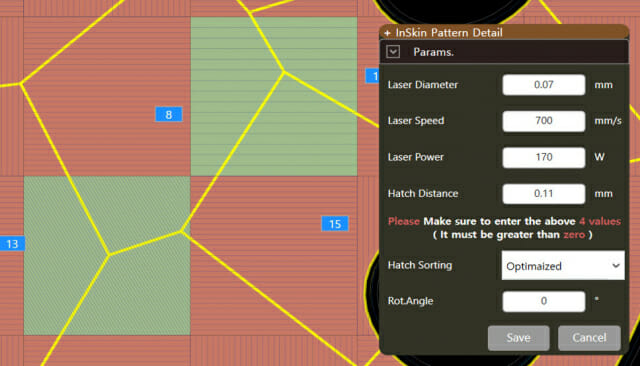

The KETI Intelligence Integrated Software Research Center has localized the generation of tool paths and functions for output code control to enable modification of process variables compatible with the characteristics of domestic equipment and collect process monitoring data.

The research team also reflected the opinions of experts in 3D printing processes working at industrial sites. Stabilization of the process offers key functions required in the field like manual editing of a tool path and formation of such a path with other variables for each area after dividing the laminated section.

The technology was developed through a project for development of software technology for laminated manufacturing controllers of industrial 3D printers with support from the Ministry of Science and ICT in 2020.

"We overcame the limitations of software for metal 3D printing, software that has been led by advanced economies, and implemented the ideas of domestic process experts," KETI President Shin Hee-dong said. " KETI will keep seeking process autonomy in metal 3D printing to contribute to raising the competitiveness of domestic manufacturing," he added.

Write to Hae-Sung Lee at ihs@hankyung.com

More to Read

-

ConstructionHyundai E&C creates world's first children's playground using 3D printing

ConstructionHyundai E&C creates world's first children's playground using 3D printingNov 25, 2022 (Gmt+09:00)

1 Min read

Comment 0

LOG IN