Tech, Media & Telecom

For South Korea, US EV subsidies both give and take away

Restrictions on subsidies in US climate law would hurt some foreign automakers, but South Korea’s battery companies still look well-placed

By The Wall Street Journal Oct 13, 2022 (Gmt+09:00)

3

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

South Korean automakers may be hurt by the legislation. But its battery makers, including global heavyweight LG Energy Solution Ltd., might benefit down the road.

Washington’s revised $7,500 credit for new EV purchases now require those cars to be assembled in the U.S. That creates a problem for South Korean carmakers Hyundai Motor Co. and its affiliate Kia Corp. They have factories in the U.S. for their gasoline-powered cars, but their EVs are currently made in Korea. This put their EVs—currently among the best-selling ones in the U.S.—in a disadvantageous position against competitors. That has already caused unease in Seoul.

Hyundai’s $5.5 billion EV and battery factory in Georgia is only set to open in 2025. The company might try to speed up its plan or repurpose some existing production lines for EVs, but buyers of its cars may miss out on the subsidies for a long stretch of time.

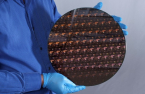

South Korean battery makers, however, are in a better position. Starting next year, cars qualifying for the EV credit will also need a certain percentage of their battery’s raw materials and components to come from the U.S.—or from countries that have a free-trade agreement with it. Those thresholds will rise over time. In addition, starting in 2024 any battery components from “foreign entities of concern,” including Russia and China, would nix access to subsidies. And from 2025, critical minerals from such entities would disqualify batteries too.

The rules are aimed at weaning the EV industry off dependence on China for battery materials. Most such materials aren’t mined in China, but the country processes most of them. China has 70% of the world’s production capacity for cathodes and 85% for anodes, both components of a battery, according to the International Energy Agency. It also has more than half of global processing and refining capacity for lithium, cobalt and graphite.

So sourcing materials and components without going through China would be a challenge in the near term. But that is a problem for everyone. South Korean battery makers, with their experience and expertise, should still benefit—especially since South Korea, unlike Japan, has a free-trade agreement with the U.S.

South Korean companies such as LG Energy and Samsung SDI Co. are among the world’s top battery makers. EV makers in the U.S. will still likely source from them as long as they can make sure their supplies are compliant with the IRA requirements. In fact, battery makers that manage to do so will have stronger bargaining power with the automakers, since the rules are so onerous.

LG Energy’s joint-venture battery cell plant with General Motors in Ohio has already started production while it is building another plant in Michigan. Citi says LG Energy should be the best positioned as it has already secured a significant part of its lithium needs from non-China suppliers. Resource-rich countries such as Australia, Canada and Chile all have free-trade agreements with the U.S.

Loosening China’s grip on battery materials isn’t an easy task. But the U.S. will entice battery makers with its huge market to try. South Korean battery makers are up to the challenge.

Write to Jacky Wong at jacky.wong@wsj.com

More to Read

-

Business & PoliticsTrump Jr. meets Korean business chiefs in back-to-back sessions

Business & PoliticsTrump Jr. meets Korean business chiefs in back-to-back sessionsApr 30, 2025 (Gmt+09:00)

-

Korean chipmakersSamsung in talks to supply customized HBM4 to Nvidia, Broadcom, Google

Korean chipmakersSamsung in talks to supply customized HBM4 to Nvidia, Broadcom, GoogleApr 30, 2025 (Gmt+09:00)

-

EnergyLS Cable breaks ground on $681 mn underwater cable plant in Chesapeake

EnergyLS Cable breaks ground on $681 mn underwater cable plant in ChesapeakeApr 29, 2025 (Gmt+09:00)

-

Business & PoliticsUS tariffs add risk premium to dollar assets: Maurice Obstfeld

Business & PoliticsUS tariffs add risk premium to dollar assets: Maurice ObstfeldApr 29, 2025 (Gmt+09:00)

-

Comment 0

LOG IN