Steel

POSCO to produce low-carbon steel raw material in Australia

The steelmaker will make Down Under hot briquetted iron, which is crucial for the adoption of electric furnaces

By Feb 14, 2023 (Gmt+09:00)

1

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

South Korea's top steelmaker POSCO has launched a project in Australia to produce hot briquetted iron (HBI), an essential raw material for the adoption of electric furnaces.

Australia is a key partner country in which POSCO Group has invested over 4 trillion won ($3.1 billion) in resource development.

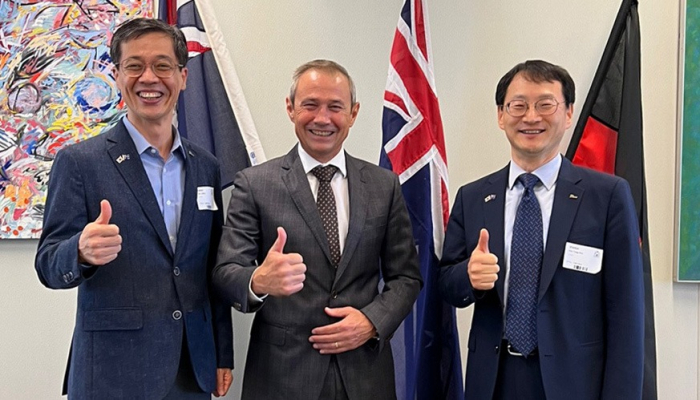

The company on Monday said Kim Yong-soo, POSCO's purchasing and investment director, from Feb. 8-10 visited Perth, Western Australia, for talks with the state's Deputy Premier Roger Cook, Minister for Mines and Petroleum, Energy, Corrective Services and Industrial Relations Bill Johnston, and Development WA Chief Operations Officer Dean Mudford.

In working-level talks that were follow-ups to discussions last month on new business cooperation between Western Australia Premier Mark McGowan and POSCO Group Chairman Choi Jeong-Woo, Kim sought cooperation and support for his company's HBI project in the state.

HBI removes oxygen from iron ore to produce direct reduced iron that is converted into briquettes and pressed and reprocessed into a shell-like shape. This is a key material in the production process for high-grade steel using electric furnaces.

In December last year, POSCO received allocation for a site at Western Australia's Boodarie Strategic Industrial Area after filing in May an application for a land lease with the state government. The HBI project will start full-scale production after remaining procedures such as licensing are finished.

Write to Seo-Woo Jang at suwu@hankyung.com

More to Read

-

EnergyPOSCO to treble natural gas production in Australia by 2025

EnergyPOSCO to treble natural gas production in Australia by 2025Jun 17, 2022 (Gmt+09:00)

2 Min read -

BatteriesPOSCO to invest $4 bn in Argentina battery materials project

BatteriesPOSCO to invest $4 bn in Argentina battery materials projectMar 22, 2022 (Gmt+09:00)

2 Min read -

Carbon neutralityPOSCO to build mini mills for carbon neutrality

Carbon neutralityPOSCO to build mini mills for carbon neutralityDec 20, 2021 (Gmt+09:00)

5 Min read -

Corporate restructuringPOSCO approves holding company plan for eco-friendly business

Corporate restructuringPOSCO approves holding company plan for eco-friendly businessDec 10, 2021 (Gmt+09:00)

5 Min read -

Carbon neutralityPOSCO partners with Australia’s Roy Hill for carbon neutrality initiatives

Carbon neutralityPOSCO partners with Australia’s Roy Hill for carbon neutrality initiativesAug 02, 2021 (Gmt+09:00)

2 Min read

Comment 0

LOG IN