Hyundai Wia commercializes autonomous logistics robots

This company's robots to be supplied to Hyundai Motor's EV plant in the US from 2024

By Apr 25, 2023 (Gmt+09:00)

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

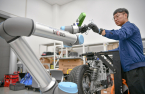

Hyundai Wia, the second-largest auto parts supplier in South Korea after Hyundai Mobis, announced on Tuesday that it will begin commercializing autonomous mobile robots (AMRs) and fixed-route automated guided vehicles (AGVs) for transporting goods to their destination.

These robots will be supplied to Hyundai Motor Group's electric vehicle plant in the United States, called Hyundai Motor Group Metaplant America (HMGMA), and to Hyundai Mobis' US factory from 2024.

The AMRs are divided into two models, with maximum loading capacities of 1,000 kg and 300 kg, respectively. They use LiDAR sensors to create real-time maps of the factory and transport goods on their own.

Hyundai Wia has classified hazardous areas separately when logistics robots create maps to generate the optimal route. The LiDAR sensor is equipped with a 3D camera to improve driving stability. The system uses the LiDAR sensor to primarily identify obstacles and uses the camera to confirm any situation that the LiDAR cannot recognize, thereby avoiding collisions during transportation.

In addition, Hyundai Wia has combined Internet-of-Things (IoT) and artificial intelligence (AI) technologies to enable the robots to understand the situation and environment in the factory, and to respond flexibly even when processes change or various types of robots are operated simultaneously.

A Hyundai Wia official stated that "We have made the AMR capable of setting its own path and perfectly transporting the items required for production, making it an innovation in electric vehicle logistics that can handle any situation flexibly."

Meanwhile, AGVs are responsible for moving vehicle bodies and parts along a predetermined path to improve productivity.

The company plans to develop the AMRs and AGVs using an integrated modular architecture (IMA) system. Recently, IMA has been applied to complete vehicle development to quickly meet diverse customer demands through standardization and modularization of key components.

Write to Nan-Sae Bin at binthere@hankyung.com

-

ConstructionHyundai E&C, Samsung C&T to jointly establish construction robot ecosystem

ConstructionHyundai E&C, Samsung C&T to jointly establish construction robot ecosystemApr 11, 2023 (Gmt+09:00)

1 Min read -

RoboticsHyundai Motor, Kia partner with DeepX to develop robotics services

RoboticsHyundai Motor, Kia partner with DeepX to develop robotics servicesMar 24, 2023 (Gmt+09:00)

1 Min read -

-

RoboticsHyundai Mobis to use self-running robots at Ulsan plant

RoboticsHyundai Mobis to use self-running robots at Ulsan plantNov 28, 2022 (Gmt+09:00)

1 Min read -

AutomobilesHyundai to set up AI robotics R&D center near Boston

AutomobilesHyundai to set up AI robotics R&D center near BostonAug 12, 2022 (Gmt+09:00)

1 Min read -

RoboticsHyundai Robotics, Vodafone to provide service robots in Germany

RoboticsHyundai Robotics, Vodafone to provide service robots in GermanyMay 31, 2022 (Gmt+09:00)

2 Min read -

RoboticsHyundai Wia likely to deploy smart robots at Georgia EV plant

RoboticsHyundai Wia likely to deploy smart robots at Georgia EV plantMay 24, 2022 (Gmt+09:00)

1 Min read -

AutomobilesHyundai Motor launches robotaxi service in upscale Gangnam district

AutomobilesHyundai Motor launches robotaxi service in upscale Gangnam districtFeb 09, 2022 (Gmt+09:00)

4 Min read -

Future mobilityHyundai Motor chairman sees future in self-driving, robot businesses

Future mobilityHyundai Motor chairman sees future in self-driving, robot businessesJun 16, 2021 (Gmt+09:00)

2 Min read