Shipping & Shipbuilding

Hanwha Ocean mulls large investments in warship facilities

Hanwha Ocean is competing with HD Hyundai Heavy Industries for a $638 million Navy deal to build frigates

By Jul 06, 2023 (Gmt+09:00)

1

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

Hanwha Ocean Co., the world’s fourth-largest shipbuilder, is considering large investments in new facilities to manufacture warships as the company aims to win an 830 billion won ($638 million) project to build two next-generation frigates for South Korea.

The company, formerly Daewoo Shipbuilding & Marine Engineering Co., said on Thursday it is mulling the construction of an indoor factory to produce two warships at the same time and a multi-purpose assembly plant dedicated to naval vessels. The South Korean shipbuilder is expected to spend more than 100 billion won on the facilities, industry sources said.

“The indoor factory is expected to allow enough time to reflect the improvement and supplementation requests from the Navy while preventing the production of ships for export from interfering with works for South Korea,” said a Hanwha official.

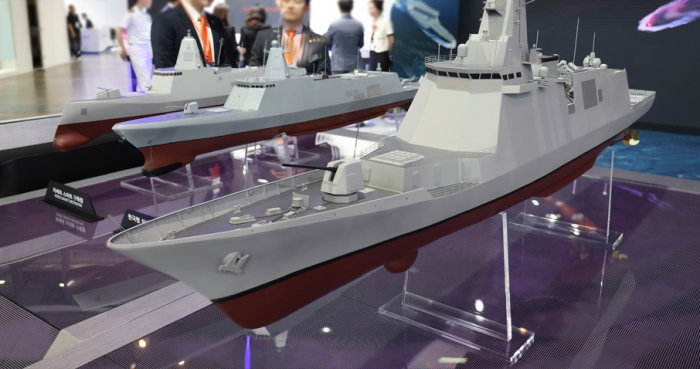

The consideration came as the South Korean shipbuilder is competing with its larger rival HD Hyundai Heavy Industries Co. on the government project, called the FFX Batch-III, to build two 3,500-ton frigates for the Navy.

INDOOR FACTORY

The indoor plant is expected to improve the quality of naval vessels and help deliver them on time, Hanwha said.

The facility will reduce the influence on warship production of inclement weather such as storms, while minimizing contamination or loss of vessel equipment from the air or other pollutants, according to Hanwha.

The plant is expected to shorten the manufacturing process as it will be equipped with two 300-ton-cranes, the largest indoor derrick in the country, which will enable the shipbuilder to use large-scale blocks, the company said.

That is predicted to result in quality improvement as the reduction of production processing time will allow time for test sailing, it added.

The multi-purpose assembly plant will expand its production capacity of warships and improve safety through an automated process, Hanwha said. The company plans to install equipment to minimize hull deformation during assembly work to build high-quality naval vessels with maximum operating performance.

(Updated with investment estimate)

Write to Hyung-Kyu Kim at khk@hankyung.com

Jongwoo Cheon edited this article.

More to Read

-

Mergers & AcquisitionsDaewoo Shipbuilding enters new chapter as Hanwha Ocean

Mergers & AcquisitionsDaewoo Shipbuilding enters new chapter as Hanwha OceanMay 23, 2023 (Gmt+09:00)

2 Min read

Comment 0

LOG IN