Get It Made in Korea

QNES Global provides its customers micro-injection molding services and develops its own micro-injection molding machines.

Key facts

| Industry | Injection molding |

| Mainstay products/services | Micro injection molding, on-demand product/mold development to production on a turnkey basis |

| Technology forte | Micro injection molding service, micro injection molding machine development |

| Main customers | Electronics, chemical companies, state-run and university-run research labs in Korea |

| Headquarters | Incheon, South Korea |

| Overseas expansion | Mold factory, R&D center in Korea |

| Founding year | 2018 |

Why it stands out

QNES Global dreams big to lead micro injection molding market┬Ā

Despite its short corporate history, QNES Global Co. is ready to become a disruptor in the South Korean injection molding industry with micro injection molding, which is often compared to the once-hyped 3D printing.

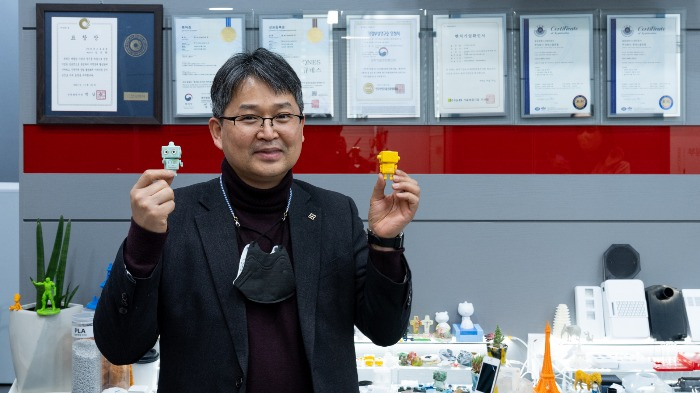

ŌĆ£Micro injection molding machines will make it easier for customers to access injection molding and revitalize the molding industry by lowering the entry barriers,ŌĆØ said Kang Jin-hwan, the founder and CEO of QNES Global. ┬Ā┬Ā

QNES Global is best known for its micro injection molding machines, which it first developed in 2019, just one year after the companyŌĆÖs inception in 2018.

Recognized for its proprietary technology in micro injection molding, QNES Global was chosen as an excellent manufacturing startup by Incheon Startup Bench Fair in 2021. It has registered a few patents regarding injection molding machine parts -- nozzle and cylinder.

MICRO INJECTION MOLDING

QNES Global is the first Korean company to adopt a micro injection molding process, Kang said.The process is suitable for producing micro parts -- as small as 0.1 gram (g) -- or products in low volumes such as 300 or fewer.

The lead time from product design to production with a micro injection molding machine is shorter than a quick delivery molding (QDM) process, which is suitable to produce 1,000 to 5,000 pieces, according to QNES Global.

It also costs less than QDMŌĆÖs production costs. Compared to the mass production injection molding, micro injection molding costs can be cut to a whopping one-tenth, according to the company. ┬Ā┬Ā

It is even faster and cheaper to churn out products compared to 3D printers, the company said.

With a QNES micro injection molding machine, it takes one to two minutes from the injection of molten resin to the ejection of a molded, finished product. It takes about four to five hours for the same process with a 3D printer.

The strength of a product made with micro injection molding is more robust than a 3D printer-made product, QNES Global said.

The Korean startup benchmarked Japan-made micro injection molding machines to produce its own, but QNES Global machines can use more diverse types of materials including acrylonitrile butadiene styrene resin (ABS), thermoplastic polyurethane (TPU), polypropylene (PP), poly lactic acid (PLA), styrene-acrylonitrile copolymers (SAN) and more than those from the US, the UK, Japan and China.

Currently, QNES Global sells three different micro injection molding models -- MD-20, AD-30 and MD-25.

Micro injection molding is expected to become popular in line with the growing demand for small-batch production that requires less investment in tooling and materials while ensuring the fast market entry of new products and the production of complicated small geometries with maximum possible accuracy and precision.

Growing demand for the miniaturization of automotive, medical, electronics and telecommunications devices is also expected to drive the need for micro injection molding of smaller components.

With QNES GlobalŌĆÖs plastic shredder machine, S-2, its micro injection molding machines make it easier to recycle plastics by turning the shredded plastics into a completely different plastic product, an easy way to live a greener life.

ONE-STOP SOLUTION FOR PRODUCT DEVELOPMENT

QNES Global makes not only micro injection molding machines but also offers one-stop product development and manufacturing services.

Its production service starts with product planning and then moves to the next stages including design development and device and circuit development for prototype production. It uses injection molding to produce a final product.

The company can help businesses of all sizes turn their ideas into real products on a turnkey basis production service with its R&D center and factory in Korea.

Its customer can receive a finished product in a small volume even in 24 hours if it has a modeling file, according to QNES Global. ┬Ā

It develops and produces medical device cases, parts and consumables, tumblers, pumps and precision plastic parts.

BUSINESS PARTNER OF SMALL BUSINESSES

QNES Global actively works with small businesses, startups, and state-run and university-run research labs opting for low-volume production.┬Ā┬ĀBut it also has major Korean conglomerates as its customers, including LG Electronics, Lotter Chemical and Daesang Group.

Write to Sookyung Seo at skseo@hankyung.com

Jennifer Nicholson-Breen edited this article.