Electric vehicles

Samsung Electro-Mechanics unveils high-capacity MLCCs for EVs

The South Korean electronic parts maker has been expanding its automotive business to tap into EV market growth

By May 16, 2023 (Gmt+09:00)

2

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

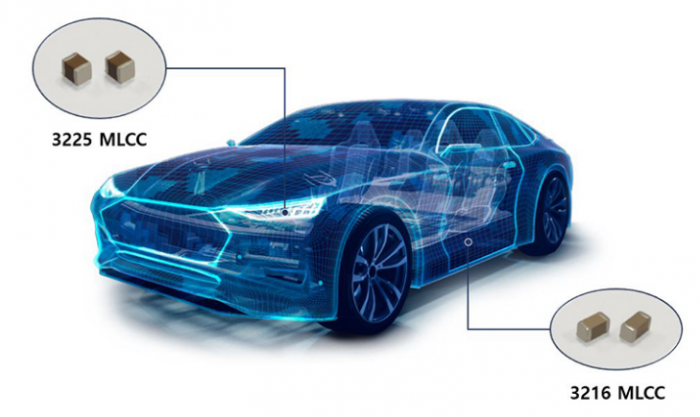

Samsung Electro-Mechanics Co., a South Korean electronic components maker, on Tuesday showcased two new multi-layer ceramic capacitors (MLCCs) with the world’s largest capacity for electric vehicles as the company aims to expand its presence in the automotive electronics sector amid surging demand for the eco-friendly cars.

MLCCs are tiny components that control the flow of electricity in a variety of products including cars, smartphones and laptops.

A car needs up to 15,000 MLCCs, which are usually more expensive than such components for IT devices, according to Samsung Electro-Mechanics. The global automotive MLCC market was forecast to grow 22.4% to $4 billion by 2026 from an estimated $2.9 billion this year, the company said.

MLCCs for EVs need to withstand the high power voltage transmitted from batteries for ultra-fast charging and smooth power transmission as the eco-friendly automobiles are operated on high-voltage battery systems such as onboard chargers. MLCCs must also have enough capacity to assist in the stable performances of semiconductors.

FOR ELECTRIFICATION SYSTEM, LED HEADLAMPS

Samsung Electro-Mechanics said it has developed an MLCC with 33 nanofarad (nF) capacity and 250 voltage. The existing 250 V MLCC’s maximum capacity is 22 nF. Samsung Electro-Mechanics’ latest MLCCs will be used for the electrification system, a core component in EVs.

It also unveiled an MLCC for 125 Celsius degrees with 10 microfarad capacity and 100 V, a capacity double that of existing models. The product will be applied to light-emitting diode (LED) headlamps.

The new MLCCs are likely to be used for advanced driving assistance systems (ADASs), chassis and infotainment systems as they met the AEC-Q200 standard, the global stress resistance criterion for passive electronic components to be used in the automotive industry.

“We established a full lineup of the automotive MLCCs with the development of products for EVs,” said Samsung Electro-Mechanics CEO Chang Duckhyun in a statement.

Samsung Electro-Mechanics aims to raise its share in the automotive electronics MLCC market by improving technology competitiveness and strengthening its production capacity, Chang said.

The company has been expanding its automotive electronics business, especially for EVs, to take advantage of the boom in the global eco-friendly vehicle sector.

Write to Jeong-Soo Hwang at hjs@hankyung.com

Jongwoo Cheon edited this article.

More to Read

-

Corporate strategySamsung Electro-Mechanics to focus on IT, automotive electronics sectors

Corporate strategySamsung Electro-Mechanics to focus on IT, automotive electronics sectorsMar 10, 2022 (Gmt+09:00)

1 Min read -

AutomobilesSamsung Electro-Mechanics aims to take lead in MLCC market

AutomobilesSamsung Electro-Mechanics aims to take lead in MLCC marketAug 13, 2021 (Gmt+09:00)

1 Min read -

Comment 0

LOG IN