Batteries

LG Energy, GM to inject another $275 mn in Tennessee plant

Following the initial $2.4 billion investment, the facilities will increase annual battery production capacity from 35 GWh to 50 GWh

By Dec 04, 2022 (Gmt+09:00)

1

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

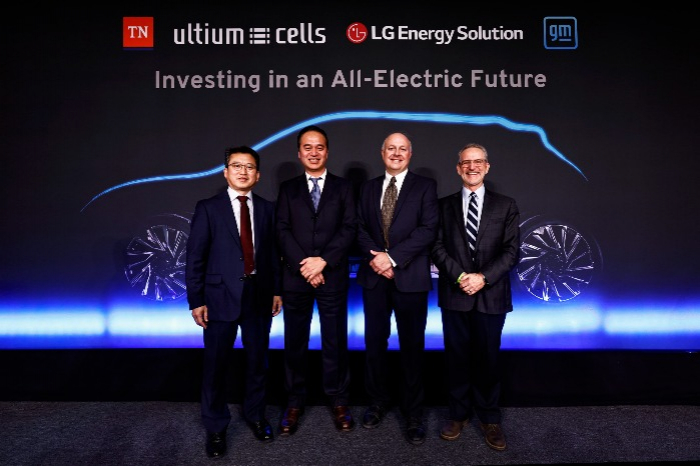

South Korean battery maker LG Energy Solution Ltd. and General Motors Co. plan to inject an additional $275 million in a US electric vehicle battery plant, under construction in Spring Hill, Tennessee, raising its production capacity by 40%.

The two firms’ joint venture Ultium Cells LLC said Friday it is aiming to increase the plant’s annual output from 35 gigawatt-hours (GWh) to 50 GWh, as well as ramp up job creations by 400 to around 1,700.

Ultium Cells announced in April 2021 that it will establish the plant with $2.4 billion. The Tennessee-based facilities are set to start full operations in late 2023.

The JV is taking the appropriate steps to support GM’s plan for more than 1 million units of EV capacity in North America by mid-decade, Tom Gallagher, Ultium Cells LLC vice president of operations, said in a statement.

In Addition to the Tennessee-based plant, Ultium Cells is constructing an EV battery factory in Lansing Delta Township, Michigan and will begin production in late 2024. The JV also started production in a battery plant in Warren, Ohio in August of this year.

Ultium Cells expects to have more than 130 GWh of battery cell capacity when all three facilities are at full production capacity.

Separately from the JV's project, LG Energy Solution’s parent LG Chem Ltd. is building a $3.2 billion plant in Clarksville, Tennessee, to manufacture key battery component cathode.

It aims to make 120,000 tons of the battery material yearly, which is the largest production capacity in the US and enough to manufacture batteries for 1.2 million units of EVs. The cathode plant will start mass production in late 2025.

Write to Hyung-Kyu Kim at khk@hankyung.com

Jihyun Kim edited this article.

More to Read

-

BatteriesLG Energy Solution diversifies supply chains to respond to US IRA

BatteriesLG Energy Solution diversifies supply chains to respond to US IRANov 11, 2022 (Gmt+09:00)

1 Min read -

BatteriesLG Energy set to ink graphite deal with Australia’s Syrah Resources

BatteriesLG Energy set to ink graphite deal with Australia’s Syrah ResourcesOct 20, 2022 (Gmt+09:00)

2 Min read -

-

-

BatteriesLG Energy in cobalt, lithium deals with three Canadian suppliers

BatteriesLG Energy in cobalt, lithium deals with three Canadian suppliersSep 23, 2022 (Gmt+09:00)

3 Min read

Comment 0

LOG IN