Batteries

POSCO Chem, GM to build $400 mn battery material plant in Canada

JV factory will reportedly produce 30,000 tons of cathode active material; POSCO Chem also plans to set up precursor plant in Korea

By Mar 08, 2022 (Gmt+09:00)

2

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

South Korea’s POSCO Chemical Co. and US top automaker General Motors Co. decided to build a battery material plant in Canada.

POSCO Chemical and GM planned to invest $400 million from next year in the joint venture factory in Bécancour, Quebec to produce cathode active material, according to both companies. The plant is known to have an annual capacity of 30,000 tons.

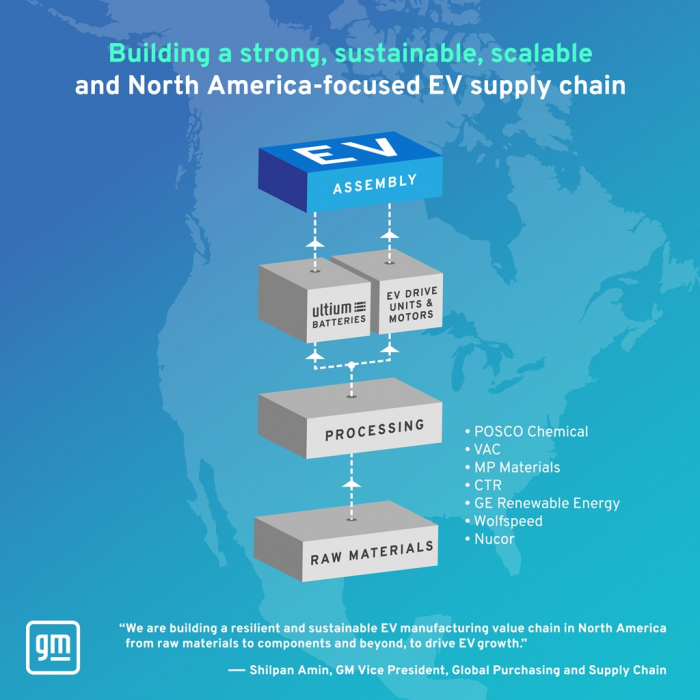

In December 2021, GM and POSCO Chemical unveiled a plan to set up a JV to churn out high-nickel cathode materials from 2024 and supply them to Ultium Cells LLC, GM's EV battery cell manufacturing JV with South Korea’s LG Energy Solution Ltd. Ultium’s batteries will power GM’s electric vehicles such as the Chevrolet Silverado EV, GMC HUMMER EV and Cadillac LYRIQ.

“GM and our supplier partners are creating a new, more secure and more sustainable ecosystem for EVs, built on a foundation of North American resources, technology and manufacturing expertise,” said Doug Parks, GM executive vice president, Global Product Development, Purchasing and Supply Chain.

POSCO Chemical said Bécancour was optimal for the new plant as the industrial city in southern Canada is close to mines while having logistics facilities, industrial infrastructure and ample hydropower renewable energy.

EXPAND BATTERY MATERIAL SUPPLY CAPACITIES IN NORTH AMERICA

GM plans to have capacity to build 2 million EVs worldwide, including 1 million units in North America, by the end of 2025.

POSCO Chemical, which has already been supplying both cathode and anode materials to GM, aims to establish a supply chain of key battery materials in North America based on the factory, expanding its global presence.

The regional EV battery market is expected to surge to 143 gigawatt-hours (GWh) in 2023 and 286 GWh in 2025 from 46 GWh last year with an average growth of 58% a year.

“POSCO Chemical is set to expand battery material supplying capability across North America through establishing a cathode material plant in Canada,” said Min Kyung-Zoon, CEO of POSCO Chemical. “We will lead the successful transition to the EV era by further strengthening the strategic partnership with GM and securing a production line with world-class technological competitiveness.”

The South Korean company is expanding cathode material production capacity with targets of 280,000 tons by 2025 and 420,000 tons by 2030 from the current 105,000 tons. It will cement the tie with GM by improving cost competitiveness of raw materials such as lithium, nickel and graphite.

PRECURSOR PLANT IN SOUTH KOREA

Separately, POSCO Chemical Monday announced a plan to invest 600 billion won ($485.4 million) in a precursor plant in South Korea.

The company will build the factory from this year to 2026 with an annual capacity of 100,000 tons of precursor, enough for cathodes to produce batteries for 1.2 million EVs.

The precursor is a material created by mixing nickel, cobalt and manganese, and is added to lithium to make cathodes.

POSCO Chemical aims to expand its precursor output capacity to 185,000 tons by 2025 from 15,000 tons this year.

Write to Jeong Min Nam at peux@hankyung.com

Jongwoo Cheon edited this article.

More to Read

-

BatteriesPOSCO Chemical, GM to launch new battery material JV in US

BatteriesPOSCO Chemical, GM to launch new battery material JV in USDec 02, 2021 (Gmt+09:00)

4 Min read -

BatteriesPOSCO Chem's rise from brickworks to EV materials leader

BatteriesPOSCO Chem's rise from brickworks to EV materials leaderNov 11, 2021 (Gmt+09:00)

5 Min read -

BatteriesPOSCO Chemical to expand EV battery materials capacity in China

BatteriesPOSCO Chemical to expand EV battery materials capacity in ChinaAug 25, 2021 (Gmt+09:00)

1 Min read -

BatteriesPosco Chemical to supply EV battery materials to GM-LG Energy JV

BatteriesPosco Chemical to supply EV battery materials to GM-LG Energy JVApr 05, 2021 (Gmt+09:00)

2 Min read

Comment 0

LOG IN