Electric vehicles

Korea’s trading firms set sights on EV parts production for growth

POSCO International, Hyundai Corp., LX International aspire to be players in the EV parts business

By Feb 22, 2022 (Gmt+09:00)

2

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Mirae Asset to be named Korea Post’s core real estate fund operator

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

South Korea’s general trading companies, which usually work as middlemen linking buyers with sellers, are seeking to transform into eco-friendly companies by entering the electric vehicle parts and materials businesses.

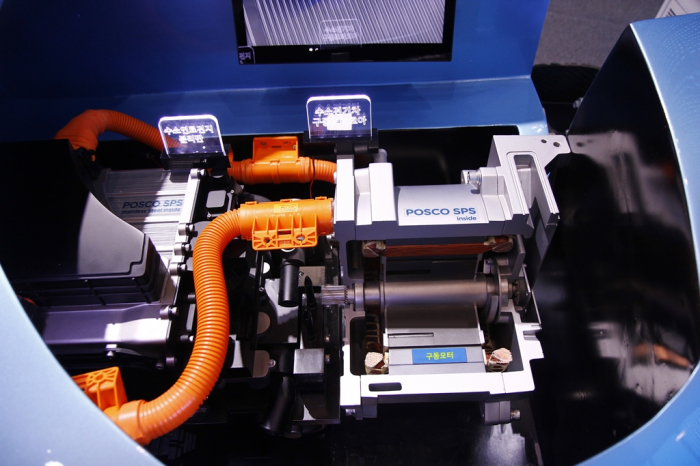

POSCO International Corp., the trading unit of steel giant POSCO, plans to establish a corporation in Slovakia for the local production of EV motor cores by the end of this year, according to industry officials on Tuesday.

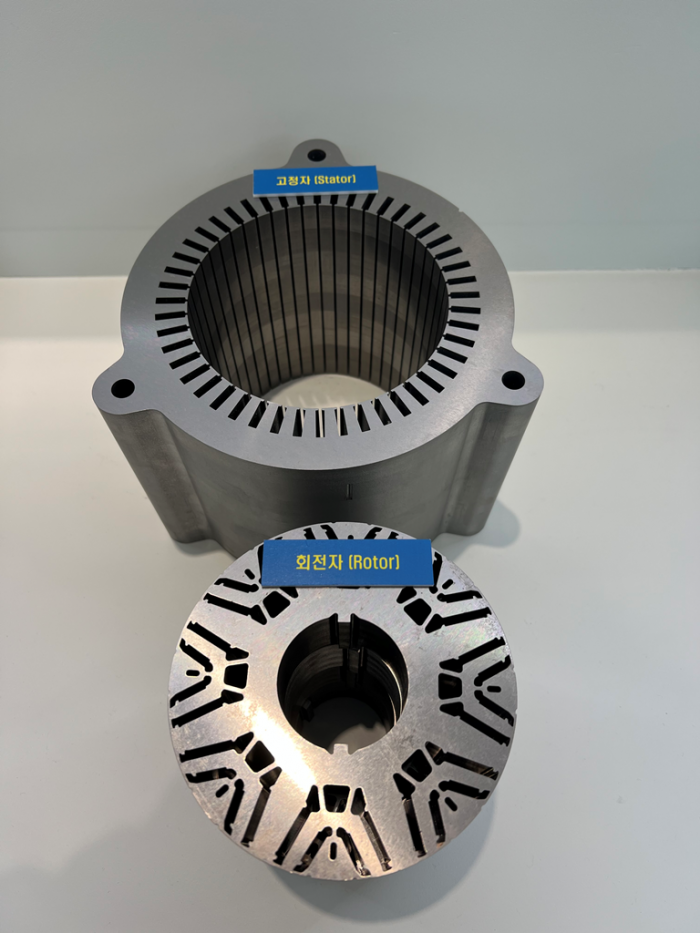

A motor core is an essential EV component that generates and pumps electricity, which works like the engine of a gasoline car.

POSCO International already operates motor core production facilities in China and India, and is building another in Mexico. The company runs the motor core business through its wholly-owned subsidiary POSCO SPS.

“We expect running EV parts production facilities to be more profitable than buying the components from suppliers. We also hope to create synergy by combing our trading business with the EV component business,” said a POSCO International official.

The company plans to raise its motor core production capacity to 4 million units by 2025 from 1.88 million units this year.

POSCO International has been actively responding to the changing vehicle market paradigm toward electric and hydrogen cars.

In December of last year, the company said it has signed a $6 million contract to supply electric vehicle components to US EV maker Rivian Automotive Inc.

NOT JUST ONLOOKERS BUT PLAYERS

Hyundai Corp., the trading arm of Hyundai Motor Group, is currently building a plastic molding and painting factory in Kaliningrad, Russia.

Once completed by the end of April, the plastic to be used for auto components will be supplied to car manufacturing plants in Kaliningrad operated by Hyundai Motor Co. and Kia Corp.

Hyundai Corp. Chairman and Co-CEO Chung Mong-hyuck has said the company will reshuffle its business portfolio to delve into the EV components business.

The company is reportedly seeking to acquire Shinki Intermobile, a Korean automobile plastic manufacturer.

LX International Corp., the trading subsidiary of LX Group, is working to acquire a nickel mine in Indonesia to secure the core material for EV batteries. Indonesia accounts for 20% of the world’s nickel reserves.

The company is known to be also looking at nickel mines in other countries for acquisition.

LX International has said it will aggressively pursue eco-friendly green projects, including biodegradable plastic production and the acquisition of battery material producers.

In November, the company said it is joining hands with SKC Co. and Daesang Corp. to build a 180 billion won ($151 million) factory for polybutylene adipate-co-terephthalate (PBAT), a raw material for biodegradable plastic.

“Korea’s trading firms don’t want to limit their role to just being an intermediary. They want to be players themselves even in the EV materials market,” said an industry official.

Write to Jeong-Min Nam at peux@hankyung.com

In-Soo Nam edited this article.

More to Read

-

Executive reshufflesPOSCO puts stability above reform in management overhaul

Executive reshufflesPOSCO puts stability above reform in management overhaulDec 22, 2021 (Gmt+09:00)

3 Min read -

Corporate restructuringPOSCO approves holding company plan for eco-friendly business

Corporate restructuringPOSCO approves holding company plan for eco-friendly businessDec 10, 2021 (Gmt+09:00)

5 Min read -

Electric vehiclesPOSCO International signs parts supply deal with US EV startup Rivian

Electric vehiclesPOSCO International signs parts supply deal with US EV startup RivianDec 02, 2021 (Gmt+09:00)

1 Min read -

BiodegradablesKorea's SK, LX, Daesang to invest $151 mn in eco-friendly plastics

BiodegradablesKorea's SK, LX, Daesang to invest $151 mn in eco-friendly plasticsNov 23, 2021 (Gmt+09:00)

2 Min read

Comment 0

LOG IN