Semiconductors

Korean chipmakers to cut core solvent imports for EUV process

Jaewon Industrial now mass produces high-purity PGMEA and supplies it to South Korean chipmakers

By Feb 18, 2022 (Gmt+09:00)

2

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Mirae Asset to be named Korea Post’s core real estate fund operator

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

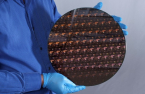

South Korean chipmakers are expected to reduce imports of a core solvent of the extreme ultraviolet (EUV) process for semiconductor manufacturing as a local company has succeeded in mass production of the material.

Jaewon Industrial Co., a petrochemical and electronic material maker, achieved commercialization of propylene glycol methyl ether acetate (PGMEA), a solvent commonly used in the semiconductor industry for the application of surface adherent on silicon wafers, according to the sector’s sources on Friday.

The company started mass production of the solvent at its plant in Yeosu, a coastal city about 340 kilometers southwest of Seoul, and has supplied it to domestic chipmakers from the end of the last year. South Korea is home to the world’s top two memory chipmakers – Samsung Electronics Co. and SK Hynix Inc.

Jaewon said it is the first South Korean company to mass produce PGMEA, although some have succeeded in developing the solvent.

TO REDUCE RELIANCE ON JAPAN, CHINA

PGMEA, made of thinner for semiconductors, washes photoresists on parts that do not have EUV photosensitized reactions in the EUV exposure process. The solvent also helps spread photosensitive materials evenly with smaller quantities when it is applied to a wafer before the exposure process.

Semiconductors manufactured through the EUV process have extremely fine circuits, so very small impurities reduce production yields. The EUV process needs PGMEA with a purity of 99.999% or higher.

Japanese makers such as Daicel Corp. have been dominant in producing such pure PGMEA, while South Korean companies previously had the technology only to increase the purity of PGMEA, not to synthesize propylene glycol monomethyl ether (PGME) into PGMEA.

So, the country has been importing extremely pure PGMEA from Japan or the lower-purity solvent from China.

Jaewon developed its own technology for PGMEA synthesis in 2018. The company last year expanded PGMEA capacity to 30,000 tons for mass production. Before that, it purified the imported PGMEA to supply to local chipmakers and display producers such as Samsung SDI Co., LG Display Co. and SK Hynix.

The company expected South Korean chipmakers to start using its PGMEA for the EUV process in the first half, reducing imports of the solvent by some 100 billion won ($83.7 million) a year.

Jaewon, founded in 1987, will consider PGMEA production in the US where it is set to build a battery materials plant, a company source said.

“We decided to build a secondary battery materials plant in the US and we're looking for a site. Once we find the land, we will mull a new PGMEA factory there,” said the source.

Write to Su-Bin Lee at lsb@hankyung.com

Jongwoo Cheon edited this article.

More to Read

-

Business & PoliticsTrump Jr. meets Korean business chiefs in back-to-back sessions

Business & PoliticsTrump Jr. meets Korean business chiefs in back-to-back sessionsApr 30, 2025 (Gmt+09:00)

-

Korean chipmakersSamsung in talks to supply customized HBM4 to Nvidia, Broadcom, Google

Korean chipmakersSamsung in talks to supply customized HBM4 to Nvidia, Broadcom, GoogleApr 30, 2025 (Gmt+09:00)

-

EnergyLS Cable breaks ground on $681 mn underwater cable plant in Chesapeake

EnergyLS Cable breaks ground on $681 mn underwater cable plant in ChesapeakeApr 29, 2025 (Gmt+09:00)

-

Business & PoliticsUS tariffs add risk premium to dollar assets: Maurice Obstfeld

Business & PoliticsUS tariffs add risk premium to dollar assets: Maurice ObstfeldApr 29, 2025 (Gmt+09:00)

-

Comment 0

LOG IN