Startups

Graphene Square aims global with mass production of 'wonder material'

By Mar 02, 2021 (Gmt+09:00)

3

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Mirae Asset to be named Korea Post’s core real estate fund operator

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

Related Articles

Graphene is often called a “wonder material” because of the extraordinary properties that come from its nano-scale structure. It is an excellent heat and electricity conductor, is elastic and was referred to by the American Chemical Society as the thinnest and strongest material available – being 100,000 times thinner than paper and 200 times stronger than steel.

South Korea’s Graphene Square Inc. is a pioneer in commercializing graphene material and graphene film. Established in 2012 as a spin-off of chemistry professor Hong Byung-hee’s lab at Seoul National University, the company researches graphene technology and provides production equipment for academic and industrial use.

The company is preparing for an IPO to fuel global expansion. It will select the underwriter this year and plans its Kosdaq listing in 2022 through the Technology Special Listing program, a system introduced in 2005 to allow promising startups to list the local bourse based on a technology evaluation conducted by Korea Exchange-designated institutions.

Graphene Square’s competitive edge lies in its proprietary chemical vapor deposition (CVD) method used for the mass production of graphene. The method is based on Hong’s own research on the synthesis of large-area graphene in 2009. His CVD research was the first of its kind on graphene, and was published in top academic journals, including Nature.

CVD is a method that transfers graphene, synthesized with a catalyst substrate such as copper at high temperatures using carbon gases, onto the target substrate.

“Simply put, our CVD technology adheres high molecular compounds onto the copper-synthesized graphene, then removes the copper using an etchant, and finally separates the graphene from the molecular compound,” explained Hong.

Graphene Square opened the door for mass production of graphene by combining the CVD technology with the "roll-to-roll" technique also devised by Hong, who still oversees the company as its CEO. The technique, apparent from its name, is just like printing newspapers as every production stage is conducted on a single production line, thus maximizing productivity.

The professor-CEO highlighted that his company’s graphene synthesis and production equipment is particularly sought after by overseas universities and research institutions, driving the vast majority of the company’s current revenue. Its most recent sales were to the Israel Institute of Technology, or Technion, which purchased three sets of CVD equipment earlier this year.

FAST-GROWING MARKET WITH MULTI-INDUSTRY APPLICATIONS

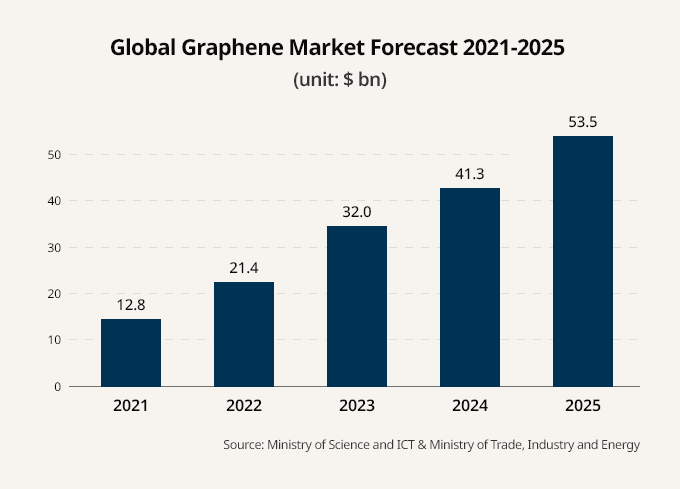

Graphene Square sees almost endless potential in the industry use of graphene, from electronic devices to electric vehicles (EVs). According to industry forecasts, the global graphene market is expected to grow at a CAGR of 65% to reach $53.5 billion by 2025.

Among the various potential segments, Graphene Square is currently focusing on the development of transparent heaters for EVs. The heater attaches graphene onto the glass film of the front windshield of the vehicle and produces heat, thereby preventing frost.

The company stated that “there is severe energy waste when EVs make hot air for defrosting. We are currently working closely with a global auto company to manufacture the transparent heaters by 2022.”

The company is also developing pellicles for the extreme ultra violet (EUV) lithography process. EUV lithography in the semiconductor industry uses EUV light that has been penetrated through the patterned EUV "mask" to draw circuits on a wafer. The pellicles are basically thin films that protect the expensive EUV masks by covering their surfaces.

Graphene Square stated that it sees a huge opportunity in the EUV sector as “the pellicle technology used in the EUV sector is not yet fully advanced in the market, despite the global trend of semiconductor manufacturers increasingly considering adopting the use of pellicles to protect the masks.”

Other areas of the company’s research for potential commercialization include applying graphene onto the current collectors of rechargeable batteries for improved capacity and charging speed, and onto bulletproof jackets.

Write to Dong-hyun Kim at 3code@hankyung.com

Daniel Cho edited this article.

More to Read

Comment 0

LOG IN