Korean SMEs

Korea contractor for TSMC, Airbus aims to top anodizing sector

The South Korean SME targets the plating market for high-tech medical equipment dominated by US companies in the long term

By Apr 29, 2022 (Gmt+09:00)

2

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

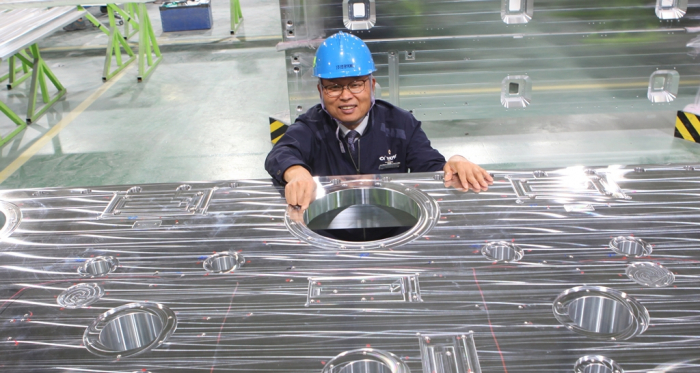

South Korea’s YKMC Inc., an integrated contract manufacturer for global companies such as Taiwan Semiconductor Manufacturing Co. (TSMC) and Airbus, aims to top the world’s anodizing industry currently dominated by US competitors by 2030.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. The process is mainly used to produce vacuum chambers for semiconductor manufacturing as the state-of-art method is much more resistant to heat or corrosion and effective in blocking current than the general plating process that coats other metals on the surface of products.

YKMC sells parts for vacuum chambers to equipment makers for global major semiconductor and displays companies such as Samsung Electronics Co., SK Hynix Inc., TSMC, Samsung Display and LG Display Co. with the anodizing technology to process materials and treat surfaces.

In 2013, the South Korean contract manufacturer sold parts applied with titanium anodizing technology to Airbus aircraft wings. The European aerospace company installed the parts to about 2,000 units of the Airbus A350.

“It is hard to find companies that can replace YKMC’s technology for display equipment and aircraft parts around the world,” said YKMC CEO Jang Kwan-Seop.

YKMC ran its plant in Asan, about 90 kilometers southwest of Seoul, at 90-100%, far higher than an average operating rate of 70% in the domestic industry, as the company had a full order book for one year.

GLOBAL NO. 1 BY 2030

The company aims to more than double its sales to 100 billion won ($80 million) by 2025 from 44 billion won last year. It also seeks a listing on the country’s junior Kosdaq in the first half of next year.

In the longer term, Jang targets the plating market for high-tech medical equipment currently dominated by US companies.

“The global anodizing market is estimated at about 150 trillion won and demand continued to increase, especially in the semiconductor equipment sector,” Jang said. “Our goal is to take the throne in the industry in 2030.”

Jang, who founded the company in 1989, was appointed as a Korean Master Hand in surface treatment by Human Resources Development Service of Korea.

He has a management philosophy to focus on the world’s only one sector that does not require competition, staying away from industries that anyone can start.

Write to Dae-Kyu Ahn at powerzanic@hankyung.com

Jongwoo Cheon edited this article.

More to Read

-

Future mobilityHyundai Motor invests in cloud, hydrogen firms for future mobility

Future mobilityHyundai Motor invests in cloud, hydrogen firms for future mobilityMar 17, 2022 (Gmt+09:00)

2 Min read

Comment 0

LOG IN