Hyundai Motor’s Uniwheel offers new paradigm for future mobility

Freeing up parts space allows PBVs more versatility, and gives EVs more floor space for extra batteries, thus longer range

By Nov 28, 2023 (Gmt+09:00)

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

Mobility has evolved at an incredible pace over the years. But there’s one thing that hardly changes – the configuration of the drivetrain.

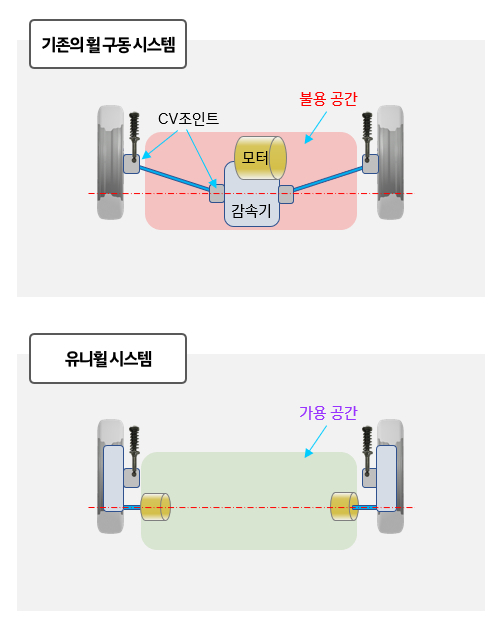

Even as vehicles are developing fast from internal combustion engine cars to electric vehicles, key components – the drive shaft, the CV joint and the reducer – have been in roughly the same place for more than a century.

If these components were packed up and moved into each wheel, it would free up the space they take up, making versatile use of the interior space, particularly for purpose-built vehicles (PBVs), and giving more floor space for EVs.

As people say “Good things come in small packages,” Hyundai Motor Co. presents an innovative space solution with its universal wheel drive system, or Uniwheel.

South Korea's top automaker on Tuesday unveiled the Uniwheel, which it said offers a new paradigm for mobility.

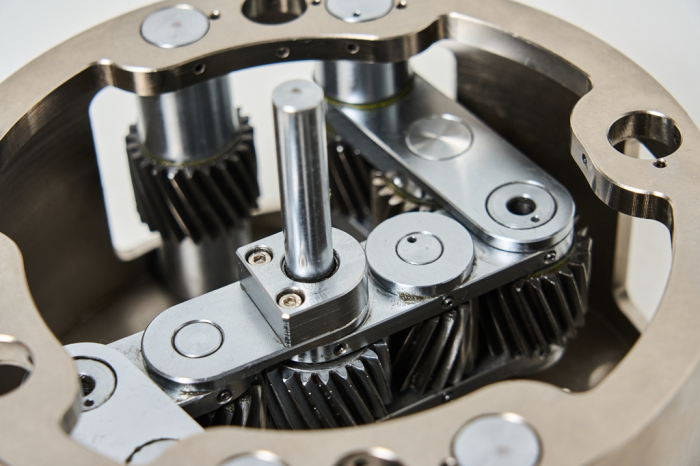

At its Uniwheel Tech Day event, Hyundai said the universal wheel drive system puts the CV joint, drive shaft and reducer into the wheels, then splits the motor into small components and moves them into each wheel.

The reducer reduces the motor rotation speed and increases torque output, and the drive shaft sends power to each wheel in between the power source and the wheel. On either side of the drive shaft is the CV joint.

Hyundai said applying the new gear structure to the vehicle and moving the drive motor right next to the wheels clears the powertrain space between the wheels.

As a result, it said the integrated wheels occupy a significantly smaller portion of an EV’s underside, allowing extra battery cells to be installed, meaning longer range.

When applied to PBVs, the Uniwheel offers a flat floor in interior designing, ensuring flexibility and scalability, including easier seat arrangements.

“The Uniwheel is all about maximizing the space between the wheels in order to maximize interior space,” said a Hyundai official. “This is achieved by miniaturizing the central motor and attaching it to each wheel.”

PASSED RIGOROUS PERFORMANCE REQUIREMENTS

The company said a Uniwheel test vehicle passed rigorous performance requirements.

In a test of the Uniwheel with a 150-millimeter stroke, the transmission efficiency was consistently satisfactory at any position regardless of the wheel's motion, it said.

More tests are underway and the gear ratio will be further adjusted to meet conditions for mass production, it said.

The Uniwheel can be adapted to different wheel sizes due to its modular design, requiring minor modifications depending on the stroke.

“This modularity means that it can be adapted to any vehicle. Even other modes of mobility like delivery robots can use the system,” Hyundai said.

The company said it will begin developing vehicles equipped with the Uniwheel next year, although it would take some years before commercialization.

Write to Nan-Sae Bin at binthere@hankyung.com

In-Soo Nam edited this article.

-

Electric vehiclesKia to build 2nd purpose-built vehicle plant in Korea

Electric vehiclesKia to build 2nd purpose-built vehicle plant in KoreaOct 13, 2023 (Gmt+09:00)

3 Min read -

AutomobilesKia scouts ex-Stellantis executive Pierre-Martin Bos as PBV director

AutomobilesKia scouts ex-Stellantis executive Pierre-Martin Bos as PBV directorJul 11, 2023 (Gmt+09:00)

2 Min read -

AutomobilesHyundai to spend $18 bn on EVs; Kia breaks ground on first PBV plant

AutomobilesHyundai to spend $18 bn on EVs; Kia breaks ground on first PBV plantApr 11, 2023 (Gmt+09:00)

3 Min read -

AutomobilesHyundai Group unveils purpose-built vehicle for airport pickup

AutomobilesHyundai Group unveils purpose-built vehicle for airport pickupSep 19, 2022 (Gmt+09:00)

1 Min read -

AutomobilesKia chooses Coupang as first partner for purpose-built vehicle rollout

AutomobilesKia chooses Coupang as first partner for purpose-built vehicle rolloutApr 15, 2022 (Gmt+09:00)

2 Min read -

AutomobilesKia set to break ground on purpose-built vehicle plant in 2023

AutomobilesKia set to break ground on purpose-built vehicle plant in 2023Mar 30, 2022 (Gmt+09:00)

2 Min read -

Chief ExecutivesKia aims to become purpose-built vehicle market leader: CEO

Chief ExecutivesKia aims to become purpose-built vehicle market leader: CEOFeb 02, 2021 (Gmt+09:00)

4 Min read