Electric vehicles

Hyundai Motor Way: New strategy to accelerate EV push

It will introduce a new modular architecture, IMA, by 2025 to achieve 2 million global EV sales in 2030

By Jun 20, 2023 (Gmt+09:00)

4

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

South Korea’s top automaker Hyundai Motor Group on Tuesday set out its vision to become a top-tier eco-friendly auto brand by accelerating its electrification, including introducing a new dedicated electric vehicle production platform.

The automotive group, which has the country’s two largest carmakers – Hyundai Motor Co. and Kia Corp. – also announced an ambitious investment plan to spend 109 trillion won ($85 billion) in EVs and other future mobility projects through 2032.

At its 2023 CEO Investor Day forum, Hyundai Motor Chief Executive Chang Jae-hoon unveiled its midterm electrification roadmap as well as financial and sales targets, as the company pursues sustainable growth as the world’s third-largest car manufacturer.

In a renewed EV push, Hyundai said it named its electrification strategy the “Hyundai Motor Way.”

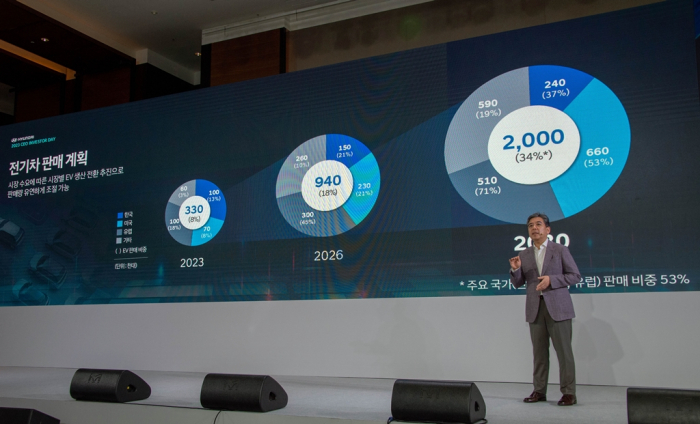

Under the new strategy, the carmaker aims to boost its annual global EV sales, including those from its premium brand Genesis, to 940,000 units by 2026 and 2 million units by 2030.

The target figures are revised upward by 100,000 units and 130,000 units, respectively, from the company’s goals announced last year.

The latest targets for 2026 and 2030 represent a threefold increase and a sevenfold rise, respectively, from this year’s EV sales goal of 330,000 units.

In April, Kia also said at its 2023 CEO Investor Day that it is raising its annual global EV sales target to 1 million units by 2026 and 1.6 million cars by 2030, up 25% and 33%, respectively, from its goals unveiled last year.

“Hyundai Motor has been preemptively responding to electrification and future technologies more than any other global carmakers. We aim to secure top-tier leadership in electrification in the near future,” Chang said at the forum.

“Hyundai Motor Way is the embodiment of our innovation DNA, which will become a source of new and sustainable revenue generation for us.”

NEW MODULAR ARCHITECTURE

Hyundai said it will introduce a new EV platform, called the Integrated Modular Architecture (IMA) – evolved from its current dedicated EV platform, the Electric-Global Modular Platform (E-GMP) – by 2025.

The IMA will be utilized not only as Hyundai’s passenger battery electric vehicle (BEV) platform but also as its exclusive purpose-built vehicle (PBV) platform, helping to streamline production processes and reduce costs, it said.

Unlike the existing BEV development system, which has different types of battery packs for each model, the IMA will be equipped with standardized battery packs, thus improving cost efficiency, according to Hyundai.

The second-generation platform will be used for 13 new dedicated EV models from Hyundai Motor Group’s three automotive brands Hyundai, Kia and Genesis through 2030.

The innovative architecture will cover nearly all vehicle classes, ranging from small and large SUVs to pickup trucks and the flagship models of the Genesis brand, it said.

TWO-TRACK APPROACH

To facilitate a rapid EV transition, the company is not only building new factories dedicated to EVs but also remodeling its existing internal combustion engine (ICE) plants in what it calls a “two-track approach” to meet the ICE vehicle demand, which is still high.

Hyundai is currently producing EVs at its plants in Korea, the US, the Czech Republic and India.

Hyundai’s first dedicated EV factory, the Hyundai Motor Group Metaplant America (HMGMA) in the US state of Georgia, is under construction.

Once up and running in the second half of 2024, it will have an annual production capacity of 300,000 vehicles.

Hyundai said the proportion of its global EV production will rise from 8% this year to 18% by 2026 and 34% by 2030.

The company’s three major markets – Korea, the US and Europe – will account for 53% of its entire EV sales by 2030, it said.

FINANCIAL GOALS

At Tuesday’s forum, Hyundai also presented its mid-to-long-term financial goals.

By 2030, Hyundai Motor targets an operating profit margin of 10% or higher from its EV business, supported by the new IMA platform.

To achieve the goal, the company said it plans to invest 109 trillion won in its future businesses through 2032, including 47.4 trillion won for R&D, 47.1 trillion won in capital expenditures and 14.9 trillion won for strategic investments.

BATTERY INVESTMENT

Hyundai said it will invest 9.5 trillion won in battery-related projects over the next 10 years to enhance internal capabilities for battery development, diversify collaborations with partners and develop next-generation batteries.

For solid-state batteries, the carmaker is collaborating with its partners, such as Solid Power, to secure raw materials and manufacturing technology, and collaborating with battery startup SolidEnergy Systems (SES) to develop lithium metal batteries.

Hyundai said it is internalizing next-generation battery element technology and expanding its talent pool.

It is also working on various battery cells optimized for each vehicle type to meet diversified market and customer needs.

The company plans to introduce competitive lithium-iron-phosphate (LFP) batteries with increased energy density and improved low-temperature efficiency in 2025. EV models equipped with LFP batteries will initially be introduced to emerging markets before expanding to advanced markets, it said.

Write to Il-Gue Kim and Nan-Sae Bin at Black0419@hankyung.com

In-Soo Nam edited this article.

More to Read

-

Electric vehiclesKia aims to launch 14 all-electric models by 2027

Electric vehiclesKia aims to launch 14 all-electric models by 2027Mar 03, 2022 (Gmt+09:00)

3 Min read -

Electric vehiclesHyundai accelerates electrification strategy, targets 7% of EV market

Electric vehiclesHyundai accelerates electrification strategy, targets 7% of EV marketMar 02, 2022 (Gmt+09:00)

4 Min read -

Carbon neutralityHyundai Motor chairman vows to go carbon neutral, stresses electrification

Carbon neutralityHyundai Motor chairman vows to go carbon neutral, stresses electrificationMay 25, 2021 (Gmt+09:00)

2 Min read -

Electric vehiclesHyundai Motor unveils all-new electric vehicle platform E-GMP

Electric vehiclesHyundai Motor unveils all-new electric vehicle platform E-GMPDec 02, 2020 (Gmt+09:00)

2 Min read

Comment 0

LOG IN