Batteries

LG Chem breaks ground on its 1st US cathode plant

The plant is set to be the largest cathode producer in the US with an annual capacity of 60,000 tons by 2026

By Dec 20, 2023 (Gmt+09:00)

3

Min read

Most Read

Hankook Tire buys $1 bn Hanon Systems stake from Hahn & Co.

NPS to hike risky asset purchases under simplified allocation system

UAE to invest up to $1 bn in S.Korean ventures

Osstem to buy BrazilŌĆÖs No. 3 dental implant maker Implacil

US multifamily market challenges create investment opportunities

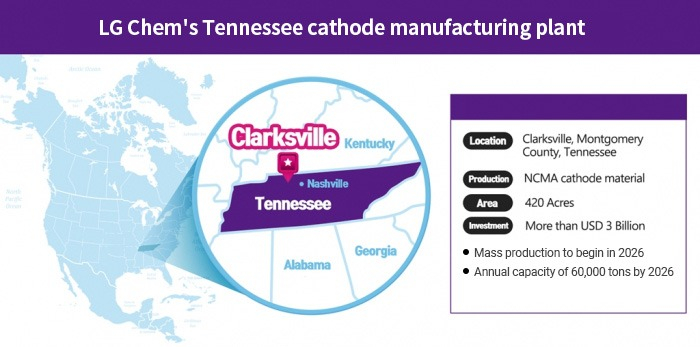

CLARKSVILLE, TN ŌĆō South KoreaŌĆÖs No. 1 chemical maker LG Chem Ltd. striving to become a leading global battery materials player broke ground on its first-ever cathode plant in the US, expected to be the biggest of its kind in the worldŌĆÖs third-largest EV market.

The plantŌĆÖs groundbreaking ceremony took place in Clarksville, Tennessee on Tuesday (local time) about a year after the Korean company and the US state government in November last year signed a memorandum of understanding to invest $3.2 billion in total to build a cathode manufacturing facility in the US. ┬Ā

The parent company of KoreaŌĆÖs largest EV battery maker LG Energy Solution Ltd. will inject about 2 trillion won ($1.6 billion) in the first phase to build a cathode plant with an annual capacity of 60,000 tons by 2026, enough to power 600,000 EVs with a range of 500 kilometers per charge.

Sitting on a 1.7 million-square-meter site, the plant is expected to embark on mass-production of nickel, cobalt, manganese and aluminum (NCMA) cathodes in 2026.

ŌĆ£The Tennessee plant will be the largest cathode-producing plant in the US,ŌĆØ LG Chem Chief Executive Shin Hak-cheol said before the groundbreaking ceremony on Tuesday. ŌĆ£Our key customers are located within a radius of 500 to 600 kilometers, which is a big advantage.ŌĆØ

Tennessee is home to Ultium Cells LLC, LGŌĆÖs battery joint venture with General Motors Co.

LG ChemŌĆÖs first battery component-producing facility in the US will supply its high nickel cathodes to Ultium and GM.

The Korean company last year signed a long-term deal with GM to supply 950,000 tons of cathodes. It also agreed with Toyota in October this year to supply 2.9 trillion won worth of cathodes.

About a week before the cathode-supplying deal, LG ChemŌĆÖs battery subsidiary LG Energy Solution bagged a deal to supply Toyota 20-gigawatt hours (GWh) worth of batteries every year for 10 years for EVs to be built at the Japanese carmakerŌĆÖs US plant.

FIT FOR IRA

LG Chem will make sure that its customers can make the best of the generous EV tax benefits under the US Inflation Reduction Act (IRA) with its new cathode factory.

The company said that it will use minerals and precursors shipped from nations with US free trade agreements (FTAs) to make cathodes that can receive tax incentives under the IRA.

Thus, the Tennessee cathode plant will secure precursors from Korea Precursor Company (KPC), a joint venture of LG Chem and Korea Zinc Inc. in Ulsan, Korea.

Combined with the IRA tax breaks, LG ChemŌĆÖs first cathode plant in the US is expected to enjoy generous tax benefits, as the plant is entitled to hundreds of billions of Korean won in tax incentives and subsidies from the Tennessee state government, said Shin.

MAJOR BATTERY MATERIAL PLAYER

The Tennessee cathode plant is also expected to accelerate LG ChemŌĆÖs plan to beef up its battery materials sales to 30 trillion won by 2030 from 4.7 trillion won in 2022.

To meet this goal, the company is seeking to diversify its customer base, currently centered around its subsidiary LG Energy Solution.

Shin expected the company to meet the goal despite the current slowdown in global EV demand.

ŌĆ£The EV marketŌĆÖs annual growth rate estimate has dropped to the 20% range from the 30% level,ŌĆØ said Shin.

ŌĆ£The annual growth rate of over 20% is still too high to achieve for most industries,ŌĆØ added Shin, suggesting the recent slowdown is not severe enough to thwart the companyŌĆÖs future growth strategy focusing on battery materials.

LG Chem plans to diversify its product portfolio through next-generation cathode material products and expand the production capacity of the Tennessee plant in response to increasing demand.

The plant will be a smart factory powered by 100% renewable energy including solar and hydropower, the company said.

Write to Sin-Young Park at nyusos@hankyung.com

Sookyung Seo edited this article.

More to Read

-

BatteriesLG Chem to supply cathode materials to Toyota's N.American plant

BatteriesLG Chem to supply cathode materials to Toyota's N.American plantOct 11, 2023 (Gmt+09:00)

1 Min read -

BatteriesLG Energy Solution to supply EV batteries to Toyota for 10 years

BatteriesLG Energy Solution to supply EV batteries to Toyota for 10 yearsOct 05, 2023 (Gmt+09:00)

3 Min read -

BatteriesLG Chem aims higher for battery materials with diverse portfolio

BatteriesLG Chem aims higher for battery materials with diverse portfolioMay 16, 2023 (Gmt+09:00)

3 Min read -

BatteriesLG Chem to build $3.2 billion US cathode plant in Tennessee

BatteriesLG Chem to build $3.2 billion US cathode plant in TennesseeNov 22, 2022 (Gmt+09:00)

3 Min read -

BatteriesLG Chem, GM in $30.6 billion EV battery materials supply deal

BatteriesLG Chem, GM in $30.6 billion EV battery materials supply dealJul 28, 2022 (Gmt+09:00)

2 Min read

Comment 0

LOG IN