Battery recycling firms aim for 90% lithium recovery rates

They are expanding into LFP battery recycling, in line with growing demand for electric vehicle LFP batteries

By Jul 31, 2023 (Gmt+09:00)

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

A growing number of South Korean companies – from battery materials makers to power facilities builders – are jumping into the waste battery recycling market forecast to grow by more than tenfold to 87 trillion won ($68 billion) by 2040.

None of them are operating their battery recycling plants at full capacity yet, but they are striving to lift their lithium recovery rates from spent rechargeable batteries above 90% within the next few years to lead the pack.

Battery recycling, so-called urban mining, means separating precious metals from batteries used for about 10 years.

Recovery rates of 80-85% for lithium and above 95% for nickel, cobalt and manganese are deemed break-even points in the industry.

EcoPro CnG Co., a subsidiary of rechargeable battery materials maker EcoPro Co., is recovering 90% of lithium from waste batteries, according to industry officials on Monday. That's on par with global battery recycling companies and the highest level among domestic firms.

It started recycling lithium and other valuable metal from old batteries in April this year in partnership with two Chinese companies – Eternal Plus and GEM.

EcoPro controls 47.5% of the joint venture in Pohang, North Gyeongsang Province, followed by Eternal with a 25% stake and GEM with a 3.75% stake.

Doosan Enerbility Co., a power plant builder, last week established subsidiary Doosan Recycling Solution specializing in battery recycling. It is aiming to extract lithium from 3,000 tons of powder sourced from spent batteries, starting in the second half of 2025.

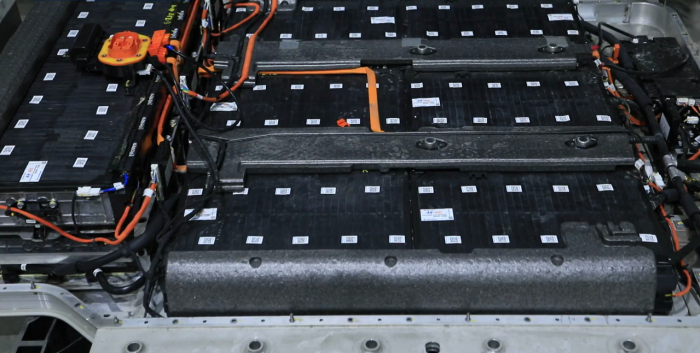

Battery materials are ground into powder, from which individual metals can be separated.

Despite being a latecomer, Doosan Enerbility has patented its lithium extraction technology. Lithium extraction requires more sophisticated technology than that needed to pull other precious metals from old batteries.

“We’ll apply our technologies accumulated to build water-treatment facilities and combustion plants to the battery recycling business,” said a Doosan Enerbility official.

SungEel HiTech Co., Young Poong Corp., Cosmo Chemical Co., Jae Young Tech Ltd. and Korea Zinc Inc. are still in the pilot stages of battery recycling.

Young Poong has reached a 90% lithium recovery rate. It will officially launch its business in 2025.

SungEel HiTech Co. boasts an 82% lithium recovery rate at its Gunsan plant in North Jeolla Province. It is aiming to lift the rate to 90% or above by the end of this year.

Based on the black powder volume extracted from lithium-ion batteries, both EcoPro CnG and SungEel HiTech each produce 12,000 tons of powder per year.

SungEel HiTech has run its metal recycling business for more than a decade. A company official said its recovery rates of lithium and other precious metals from waste batteries are high enough to stave off the competition from newcomers.

Cosmo Chemical is test-running its battery recycling plant before operating it at full capacity next year, with an aim to recover 88% of lithium from old batteries.

Jae Young Tech, in which LG Chem Ltd. had invested 24 billion won ($19 million), can recover 85% lithium from batteries. Korea Zinc did not disclose its recovery rate, which industry officials estimated at 80-85%.

Lithium tends to catch fire more easily than other metals and melts in water, so it requires high-level technologies to separate it from other battery materials and recycle at profitable levels.

Recycled batteries are regarded as hidden treasures because they are obtained without digging in the ground or developing mines, harmful to the environment.

According to research firm Rystad Energy, batteries will likely be required to contain a certain percentage of recycled lithium from around 2027.

The European Commission has introduced measures to ensure that 16% of lithium in batteries to be produced from 2030 are sourced from used batteries, with 6% of nickel and 16% of cobalt to be extracted from waste batteries, under the European Critical Raw Materials Act.

LFT BATTERY RECYCLING

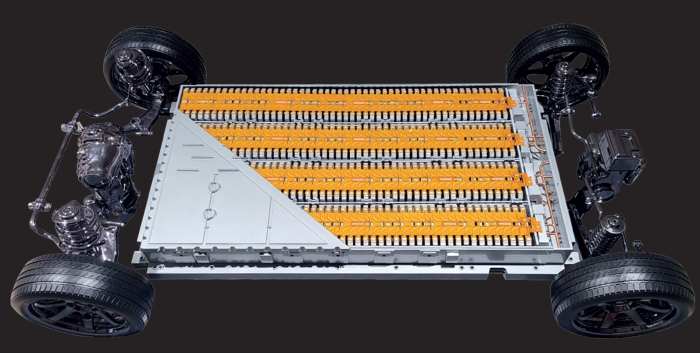

Now Korean companies are expanding into the recycling business for lithium iron phosphate (LFP) batteries, primarily produced by Chinese companies.

Compared with nickel, cobalt and manganese contained in lithium-ion batteries, iron and phosphate are cheaper. Thus, it seems unprofitable to recycle them.

Further, they produce waste materials during the recycling process, which need to be buried in the ground.

But in line with the growing demand for LFP batteries, embedded in low-priced EVs, SungEel HiTech and EcoPro CnG are developing relevant recycling technologies.

According to SNE Research, the battery recycling market is forecast to expand to about 87 trillion won by 2040, compared to 700 billion won in 2023.

Write to Mi-Sun Kang at rambutan@hankyung.com

Yeonhee Kim edited this article.

-

BatteriesDoosan to enter EV sector with battery recycling business

BatteriesDoosan to enter EV sector with battery recycling businessJul 28, 2023 (Gmt+09:00)

1 Min read -

Waste managementKPS to recycle waste batteries for Samsung Electronics

Waste managementKPS to recycle waste batteries for Samsung ElectronicsJul 04, 2023 (Gmt+09:00)

1 Min read -

BatteriesLG Energy, SK On to showcase LFP battery prototypes at InterBattery 2023

BatteriesLG Energy, SK On to showcase LFP battery prototypes at InterBattery 2023Mar 09, 2023 (Gmt+09:00)

2 Min read -

EV BatteriesTesla’s shift to LFP cells to shake global battery industry

EV BatteriesTesla’s shift to LFP cells to shake global battery industryOct 22, 2021 (Gmt+09:00)

3 Min read -