LG Energy to invest $451 mn in mass production of TeslaŌĆÖs 4680 battery cells

The conglomerate is on its way to becoming the world's first mass manufacturer of the new cell next year

By Jun 13, 2022 (Gmt+09:00)

Alibaba eyes 1st investment in Korean e-commerce platform

Blackstone signs over $1 bn deal with MBK for 1st exit in Korea

NPS loses $1.2 bn in local stocks in Q1 on weak battery shares

OCI to invest up to $1.5 bn in MalaysiaŌĆÖs polysilicon plant

Korea's Lotte Insurance put on market for around $1.5 bn

LG Energy Solution Ltd. announced Monday it will invest 580 billion won ($451 million) to manufacture battery cells for Austin-based Tesla, Inc.

The battery-making arm of LG Corp. plans to add 9 gigawatt-hours (GWh) worth of production capacity for the new 4680 cylindrical batteries at its No. 2 Ochang factory.

The battery maker also announced it would invest 150 billion won in the No. 1 Ochang factory to add 4 GWh worth of production capacity to manufacture the existing 2170 cylindrical battery cells.┬Ā

The 4680, expected to be mass produced next year, is composed of nickel, cobalt, manganese and aluminum (NCMA). The new battery has an increased nickel composition of up to 95% and added aluminum.

If and when LG Energy Solution succeeds in mass producing the new cell on schedule ŌĆō widely considered to be the battery industryŌĆÖs game-changer ŌĆō it will become the worldŌĆÖs first company to manufacture them at a large scale.┬Ā

Experts say the latest injection of funds will cement the already strong ties between the South Korean conglomerate and Elon Musk's Tesla.┬Ā

PRODUCTION CAPACITY

ŌĆ£We have decided on the investment to increase our production capabilities on the back of global automakersŌĆÖ rising interest in cylindrical batteries,ŌĆØ Kwon Yong-soo, vice chairman and CEO of LG Energy Solution said.┬Ā

The new 4780 battery cell is considered to be the most advanced version of a battery cell to be used in an EV, after the all-solid-state battery.┬Ā

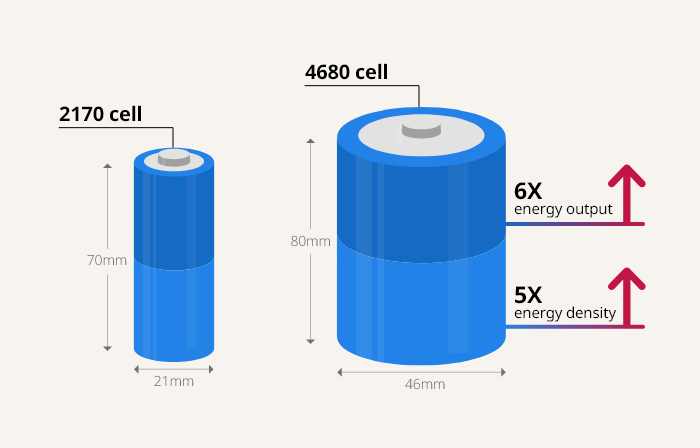

The bigger battery boasts five times the energy density and six times the output of the 2170 counterpart. In turn, an electric vehicleŌĆÖs mileage using the 4780 will increase by 16% on average.┬Ā

LetŌĆÖs put that number into perspective in terms of No. 2 Ochang plantŌĆÖs expansion.

The 9 GWh worth of production capacity per year translates into about 130,000 EVs. The figure is higher than between 108,000 and 112,500 EV production using the 2170 battery.┬Ā

Some estimate that LG could receive approximately 2 trillion won per year just on its 4680 cells orders from Tesla. In the first quarter of this year, LG Energy SolutionŌĆÖs order balance reached 200 trillion won.┬Ā

Experts forecast electric vehicles to have a higher competitive edge than engine cars once the price of a battery pack falls below $100 per kilowatt-hour. Industry insiders are hopeful this can be achieved with the new 4680.

Currently, the figure stands at around $105 per KWh.┬Ā

ŌĆ£Whereas all-solid-state batteries are expected to be mass produced in 2028 and have yet to overcome technical challenges, the 4680 cells can increase the efficiency in a short period,ŌĆØ an industry insider told The Korea Economic Daily.┬Ā

A cylindrical cell, despite being the oldest technology in the rechargeable battery industry, is considered to be more innovative than the later-introduced pouch and prismatic batteries.┬Ā

GLOBAL COMPETITORS

Taking a look at LG Energy SolutionŌĆÖs competitors for Tesla orders, Panasonic Holdings Corp. will finish the construction of a plant solely dedicated to manufacturing 4680 batteries in the United States in 2028.┬Ā

Earlier this month, Tesla reportedly received 4680 battery cell samples from the Osaka-based conglomerate.

LG is also forecast to catch up to ChinaŌĆÖs Contemporary Amperex Technology (CATL) Co., which only supplies lithium, phosphate, and iron (LFP) batteries to Tesla. While CATL plans to enter into the cylindrical battery business, industry insiders question its ability to do so as it currently trails far behind its competitors.┬Ā

Domestic battery maker Samsung SDI Co. is in the process of developing the 4680 while SK Innovation Co. only manufactures pouch cells.

Tesla has about 1 million 4680 battery cells at its manufacturing facility located in Fremont, California. But its mass production capacity is below 50% of its demand.

Write to Hyung-Kyu Kim, Han-Shin Park at khk@hankyung.com

Jee Abbey Lee edited this article.

-

ElectronicsLG Display to target 3 billion gamers with dedicated OLED

ElectronicsLG Display to target 3 billion gamers with dedicated OLEDJun 10, 2022 (Gmt+09:00)

3 Min read