Batteries

LG Energy, Stellantis to build $4.1 billion battery plant in Canada

The world’s No. 2 battery maker will also construct a $1.4 billion standalone battery plant in Arizona

By Mar 24, 2022 (Gmt+09:00)

4

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

KT&G eyes overseas M&A after rejecting activist fund's offer

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

StockX in merger talks with Naver’s online reseller Kream

Meritz backs half of ex-manager’s $210 mn hedge fund

The world’s second-largest battery maker LG Energy Solution Ltd. and multinational automaker Stellantis N.V. have agreed to build a $4.1 billion electric vehicle battery plant in Ontario, Canada to meet growing demand in North America.

The two companies said on Thursday they signed a binding, definitive agreement to launch a joint venture to invest over 5 billion Canadian dollars, or 4.8 trillion won, to manufacture cutting-edge lithium-ion battery cells and modules to meet a significant portion of Stellantis’ vehicle production requirements.

LG will own 51% of the JV, while Stellantis, the world’s No. 4 automaker, will have the remaining stake.

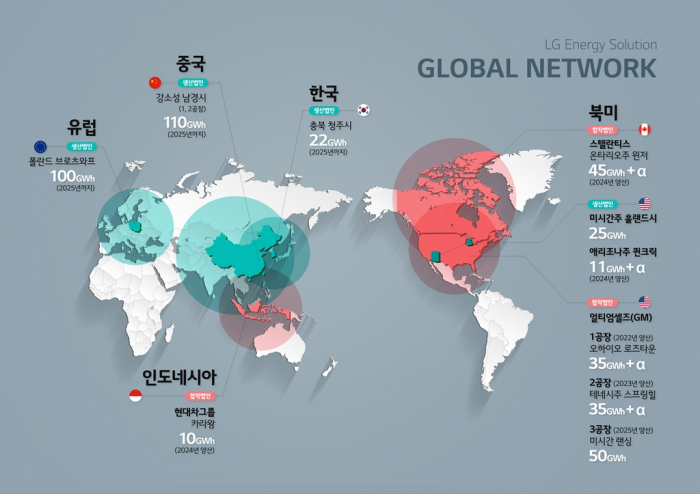

The plant, to be built in Windsor, Ontario, home to Canada’s largest automotive cluster, will have an annual production capacity in excess of 45 gigawatt hours (GWh) by 2026 and create an estimated 2,500 new jobs in the region, according to the companies.

Construction of the plant will begin later this year with an aim to start operations in the first half of 2024.

“Creating a joint venture battery manufacturing company in Canada, recognized as one of the leading nations in renewable energy resources, is key for LG as we aim to power more electric vehicles around the world,” LG Energy Chief Executive Kwon Young-soo said in a statement.

Stellantis Chief Executive Carlos Tavares said: “Our joint venture with LG Energy Solution is yet another stepping stone to achieving our aggressive electrification roadmap in the region aimed at hitting 50% of battery electric vehicle sales in the US and Canada by the end of the decade.”

As part of its 2030 business goal, Stellantis plans to have global annual battery EV sales of five million vehicles by 2030, with all of its cars sold in Europe and half of its passenger cars and light-duty trucks sold in North America electric.

Stellantis, the maker of the Jeep SUV, is a 50-50 joint venture launched in January of 2021 through the merger of US carmaker Fiat Chrysler Automobiles N.V. and French automaker PSA Groupe.

STANDALONE PLANT IN ARIZONA

Meanwhile, LG Energy said it is also spending 1.7 trillion won ($1.4 billion) to build its own battery plant in the US state of Arizona.

The plant, to be located in Creek, Arizona, will manufacture cylindrical-type batteries. LG’s other plants around the world are mostly producing pouch-type cells.

Construction of the plant with an annual production capacity of 11 GWh will start later this year, with operations slated for the second half of 2024.

Industry watchers said the Arizona plant will be supplying batteries to EV startups such as Nikola Corp., Lucid Motors and Proterra.

In November of last year, LG signed a battery supply deal with Arizona-based electric semi-truck manufacturer Nikola.

LG Energy said it plans to bring in smart factory systems to both the Arizona plant and the JV with Stellantis to improve productivity.

The Arizona factory will be LG Energy’s second standalone battery plant in the US.

LG runs its own battery plant in Michigan and last month, it said it is spending $1.7 billion to expand its annual battery production capacity in Holland, a city in Michigan, by fivefold to 25 GWh by 2025 from the current 5 GWh.

SHIFT TOWARD ELECTRIFICATION

LG’s strengthened partnership with Stellantis and the construction of another standalone battery plant in the US come as battery makers and carmakers around the globe tie up to get ahead in the shift toward electrification.

LG Energy Solution Michigan Inc., which began operations in 2012, has been supplying batteries to major US automakers, including General Motors Co., Ford Motor Co. and Chrysler.

Separately, LG Energy is running a battery joint venture, Ultium Cells LCC, with its partner GM in the US.

In January, LG and its US partner GM announced a $2.6 billion project to build their third EV battery plant in Lansing, Michigan, with a capacity of up to 50 GWh, enough for 700,000 EVs that can drive 500 kilometers on a full charge.

LG and GM are also said to be considering their fourth plant, with an expected annual production capacity of 30 GWh.

Currently, Ultium is already building two 35 GWh battery plants, one in Ohio and the other in Tennessee. The Ohio factory is set to begin operations this year and the Tennessee facility is slated to start production in 2023.

When LG’s own plant in Michigan and its JVs with GM and Stellantis are fully up and running, the Korean company’s total capacity in North America will reach more than 200 GWh, the largest among battery makers in the region.

According to market tracker IHS, the EV battery demand in North America will reach 285.8 GWh by 2025, of which nearly 70% will be supplied by LG Energy.

Write to Hyung-Kyu Kim at khk@hankyung.com

In-Soo Nam edited this article.

More to Read

-

BatteriesLG Energy considers billion-dollar battery plant in Arizona

BatteriesLG Energy considers billion-dollar battery plant in ArizonaMar 22, 2022 (Gmt+09:00)

3 Min read -

BatteriesLG Energy to spend $1.7 bn to hike Michigan battery capacity fivefold

BatteriesLG Energy to spend $1.7 bn to hike Michigan battery capacity fivefoldFeb 07, 2022 (Gmt+09:00)

3 Min read -

EV BatteriesLG Energy, GM to build $2.6 bn battery plant in Michigan

EV BatteriesLG Energy, GM to build $2.6 bn battery plant in MichiganJan 26, 2022 (Gmt+09:00)

2 Min read -

BatteriesLG Energy, Stellantis to launch $3.4 billion EV battery JV in US

BatteriesLG Energy, Stellantis to launch $3.4 billion EV battery JV in USOct 18, 2021 (Gmt+09:00)

4 Min read

Comment 0

LOG IN