Aerospace & Defense

Hanwha to develop own gas turbine engine for future growth

Hanwha Aerospace to invest $46 million in a Korean gas turbo engine plant to double its production capacity

By Jan 04, 2024 (Gmt+09:00)

4

Min read

Most Read

LG Chem to sell water filter business to Glenwood PE for $692 million

Kyobo Life poised to buy Japan’s SBI Group-owned savings bank

KT&G eyes overseas M&A after rejecting activist fund's offer

StockX in merger talks with Naver’s online reseller Kream

Mirae Asset to be named Korea Post’s core real estate fund operator

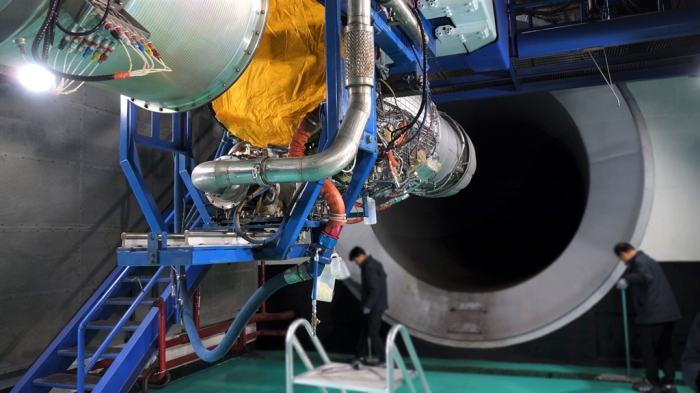

CHANGWON, South Gyeongsang Province – Hanwha Group, South Korea’s chemicals-to-defense conglomerate, is set to double its local gas turbine engine production capacity while aiming to develop its model for fighter jets to ensure future growth in the military product business.

Hanwha Aerospace Co. has set a goal of securing gas turbine engine design technology for fighter jets by 2040 with active investments in research and development, according to industry sources on Thursday. The group’s defense subsidiary plans to start the development by joining the conceptual study on engine development for aircraft weapons systems recently launched by the South Korean Defense Acquisition Program Administration.

Gas turbine engines are touted as the "heart of the defense industry” as they are used not only in fighter jets, aircraft, warships and cruise missiles but also for next-generation battle tanks and self-propelled howitzers.

“Engine technology in the defense sector is the same as semiconductor technology in the IT sector,” an industry source said.

Currently, Hanwha Aerospace is manufacturing gas turbine engines under licenses from military aircraft giants such as General Electric Co. (GE), Rolls-Royce Holdings and Pratt & Whitney. Only about 39% of the South Korean company's total gas turbine engine production costs are in the country.

WE NEED OUR OWN

Hanwha Aerospace aims to develop more than 60 types of materials in stages to build homegrown gas turbine engines.

Developing a homegrown engine is essential for the South Korean defense industry to move forward to advanced weapons from conventional arms although it usually takes 13-15 years to develop it, a Hanwha executive said.

“For up to the fourth generation fighter jets, we could domestically manufacture engines by licensed production, but from fifth-generation aircraft such as F-35 we need to buy them,” said Hanwha Aerospace Vice President Kim Kyeongwon at its gas turbine engine plant in Changwon, about 380 kilometers (236 miles) southeast of Seoul.

“We must have homegrown design technology to manufacture cruise missiles, next-generation warships, fifth-generation fighter jets and even more advanced ones, which require advanced gas turbine engines.”

Only six countries – the US, the UK, France, Russia, China and Ukraine – currently have fighter jet engine design technology.

Gas turbine engines powered by energy from compressing air and exploding it with fuel are more efficient for high-speed and rapid acceleration with better maximum power output than diesel engines.

Fighter jet engines, which make up about 20% of total warplane production costs, require the most advanced technology as they need to resist harsh environments for operations involving high altitude, speed and temperature.

Hanwha Group Vice Chairman Kim Dong-kwan, the conglomerate’s heir apparent, stressed the importance of a homegrown gas turbine engine.

“Hanwha must carry on the aircraft engine sector,” Kim told employees at the Changwon plant. “It is something meaningful that we can pass on to the next generations, regardless of business rationale.”

TO DOUBLE OUTPUT

Hanwha Aerospace plans to invest 60 billion won ($45.9 million) this year in the factory to double its annual gas turbine engine production capacity to triple-digit units, although it declined to provide output details due to security issues.

The company is scheduled to start the construction in April with a target of completion by year-end.

The expansion plans come amid growing demand as the country’s sole military aircraft manufacturer Korea Aerospace Industries Ltd. (KAI) is poised to export the KF-21, the first homegrown supersonic fighter jet and the group’s shipbuilder Hanwha Ocean Co. won a series of orders to build navy vessels.

Hanwha Aerospace, which has been manufacturing gas turbine engines for combat planes since 1980, is set to top 10,000 units in cumulative production by April.

The company, which manufactured parts only as a subcontractor in its early stage due to a lack of technology, has secured advanced production technology, leading global major engine makers such as GE to request a transfer of its technology to contractors in other countries, industry sources said.

GE moved some of its production lines to Hanwha Aerospace’s factory in Changwon, giving the South Korean company full control over parts manufacturing.

Write to Hyung-Kyu Kim at khk@hankyung.com

Jongwoo Cheon edited this article.

More to Read

-

Leadership & ManagementHanwha's heir apparent promoted as group's vice chair

Leadership & ManagementHanwha's heir apparent promoted as group's vice chairAug 29, 2022 (Gmt+09:00)

4 Min read -

Aerospace & DefenseHanwha Aerospace to develop fighter jet engine materials

Aerospace & DefenseHanwha Aerospace to develop fighter jet engine materialsJul 26, 2023 (Gmt+09:00)

1 Min read -

Aerospace & DefenseS.Korean fighter jet KF-21 makes first supersonic flight

Aerospace & DefenseS.Korean fighter jet KF-21 makes first supersonic flightJan 18, 2023 (Gmt+09:00)

1 Min read

Comment 0

LOG IN